In the highly competitive global market for packaging machinery, Masipack differentiates its offer through three of B&R’s latest innovations: mapp Technology, the Power PC 2100 for integrated visualization and control, and the ACOPOS P3 family of servo drives.

Brazil-based Masipack supplies innovative, turnkey packaging equipment solutions with over 160,000 machines installed worldwide. Masipack machines run a broad range of consumer products, while machines from sister company Fabrima focus on the unique requirements of pharmaceutical packaging. Masipack systems range from primary to end of line, from economical systems for small businesses, to systems optimized for mid-sized businesses, to fully automated systems for the largest production facilities. But the company knew that to be competitive, they would need to innovate. Explains Mauricio Moreno, President of Masipack Group., “market is constantly seeking better quality machines that increase productivity, have high availability, and are easy and low in cost to maintain.”

A break from tradition

Traditionally, Masipack had developed a bespoke control system in-house for multi head scales. They saw the need to adopt a commercial system, especially for export, to fulfill the international certifications, to meet customer specifications and assure the availability of technical support globally. In their first application for a commercial control platform – the multi head scales – the existing supplier was unable to provide vibration and strain gauge modules or sufficient control processing speed to run multi head scales. B&R could meet these requirements, plus much more.

Change for the better

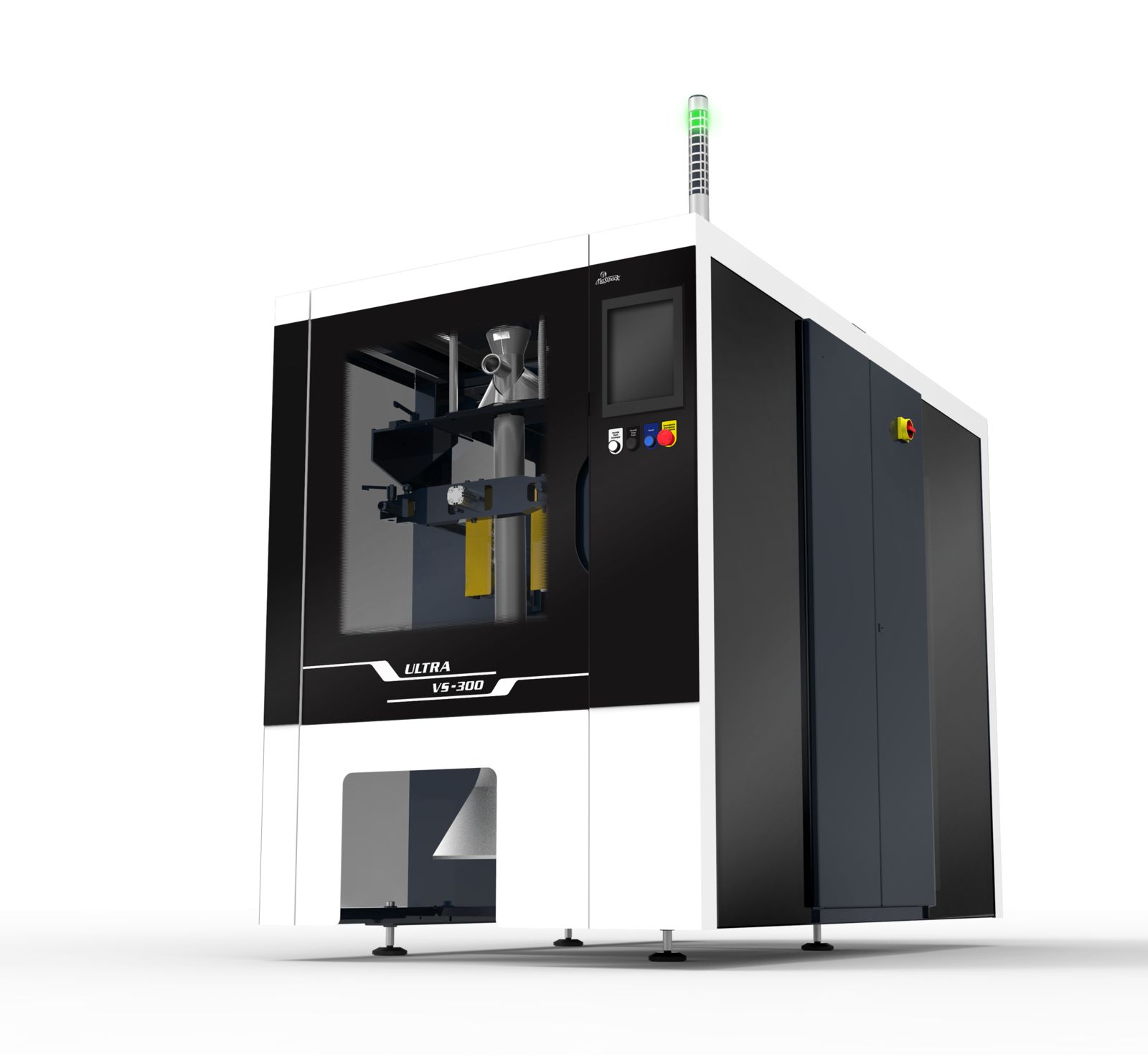

The move to B&R began with PP400 and then PP500 Power Panels, using Matlab Simulink for simulation and subsequent programming in Automation Studio. Now Masipack has standardized on the Panel PC 2100 as integrated control and operator panel with Automation Runtime embedded and customized black Masipack branded HMI bezel. “The HMI design is a differentiator,” continues Mauricio Moreno, “It is very elegant and a perfect fit with the machine design. Besides that, it is so versatile to integrate the VFFS with multi head scales. And the large 12" HMI mounted vertically allows you to display much more information.” After the multi head scales were completed converted, Masipack developed the first VFFS (Vertical Form Fill Sealing) machine in its new product range with B&R in just one week, using mapp Technology and ACOPOS P3 motion. What’s more, the Power PC 2100 integrates VFFS with scales in a single controller. Conventional control platforms require two separate controllers, saving cabinet space and communications overhead.

Precise, distributed multiaxis motion

B&R’s unique machine frame-mounted X67 stepper modules control two step motors per weigh hopper (head), also saving cabinet space and wiring. The top of the head vibrates the feeder and pre charge, then, when the bottom of the head is empty, the top motor open the hopper and the bottom of the head correctly senses the product weight. A motor at the bottom opens the head to discharge material into the former. Machines are available with up to 28 heads, with typically configurations of 14 to 24 heads. Accurate fill weights require a software filter, and with B&R control the measurement is more precise than ever before. A common application in North America is filling of vitamins into plastic bottles. Filling by weight is faster than is possible with a slat counter.

mapp Technology adapts to new requirements

Next, Masipack applied B&R to additional machines across the packaging line. Having used mapp Technology to generate modular, reusable code for the VFFS, the software has been easily modified to run different machine types. Now, Fabrima is developing pharmaceutical cartoners and blister pack machines with B&R that will comply to CFR 21 Part 11 through mapp Audit and mapp Recipe. These machines will benefit from standardizing on the PPC 2100, which provides full industrial PC capabilities and can therefore run Windows-based pharma software applications.

Efficient servo motion

The same PP2100 controller used for the scales is combined with ACOPOS P3 servo drives, delivering a faster and more cost effective solution than the previous control supplier. Along with increased performance, the ability to run up to three servos from a single, compact drive contributes once again to cabinet space and wiring reduction. In the past, Masipack used conventional single-axis servo drives. With the multiaxis P3 drives, the machines are more energy efficient because they share a common bus for regeneration. In the case where a volumetric feeder is used in place of a scale, the feeder is servo driven. One servomotor controls dosing by volume, one runs the horizontal seal bars. Continuous motion machines use a third servo for film draw.

More machines, more servos

Sachet and stick pack machines use eleven servos to individually control the multiple filling heads. Masipack also uses three to five axes per machine on its horizontal flow wrappers. Fabrima changed from a third party check weigher to develop its own check weigher controlled by B&R, with three servo axes for infeed, measurement and exit conveyors. Mauricio Moreno concludes, “The compact I/O, cabinet space savings and operator friendly HMI complement B&R’s great advantage in software development, with code that is easy to reuse in other types of machines.”

| Mauricio Moreno President, Masipack “The compact I/O, cabinet space savings and operator friendly HMI complement B&R’s great advantage in software development, with code that is easy to reuse in other types of machines.” |