Efficient – Sustainable – Innovative

In the age of Industrial IoT, concepts like modeling, simulation and virtual commissioning are quickly becoming standard procedure in the development of automation technology. Seamlessly networked development tools, unprecedented flexibility and highly efficient resource management promise to optimize the development process and get projects up and running significantly faster.

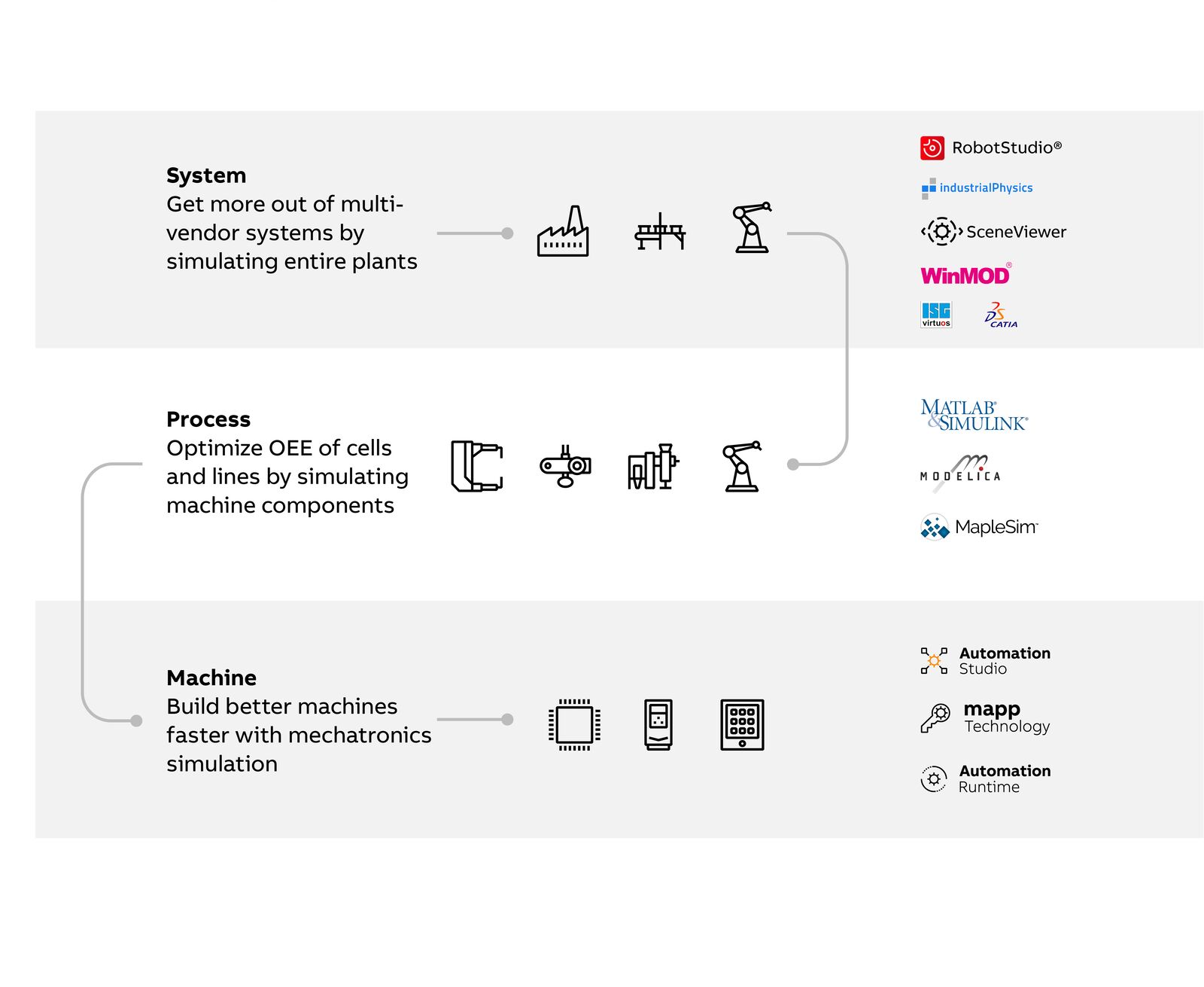

B&R supports model-based development at whatever level of detail it is implemented – with modeling, simulation and virtual commissioning woven into its entire product portfolio.

Seamless integration at all levels

At the first level, Automation Studio supports simulation of all B&R hardware components with Automation Runtime Simulation (ARsim) and ACOPOS simulation.

At the level of components and machines, B&R supports a variety of simulation and modeling tools such as MATLAB® /Simulink® and MapleSim for dynamic modeling of machines and machine components.

At the highest level, complex system processes such as material flow or entire production plants can also be simulated. To make this possible, Automation Studio features interfaces for external tools such as industrialPhysics and ISG-virtuos.

|  | ||

|---|---|---|---|

The interface between Automation Studio and MATLAB/Simulink. | The standardized interface for connecting various simulation tools. |