Frequency inverters

With scaled functionality and full integration into the B&R automation landscape, ACOPOSinverter is suited for a wide range of use, from small machine modules to complex plants.

ACOPOSinverter P66

ACOPOSinverter P76

ACOPOSinverter P86

ACOPOSinverter P64new - Retrofit for X64 (replacement parts requirements)

ACOPOSinverter P74new - Retrofit for P74 (replacement parts requirements)

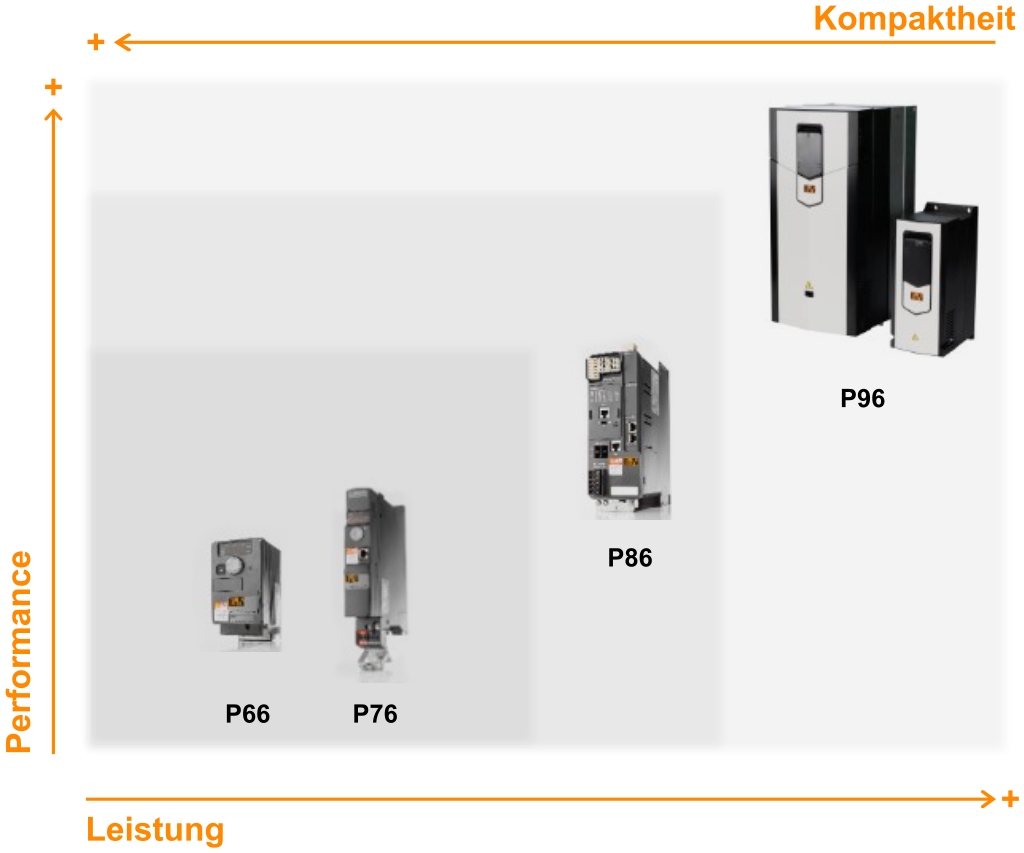

Series comparison

ACOPOSinverter P66 frequency inverters include various drive profiles for three-phase induction motors and synchronous motors with a power supply from 200 to 600 V and a power rating from 0.18 to 15 kW. The combination of an ACOPOSinverter P66 and an encoderless synchronous motor is very compact, contributing significantly to the reduction of the machine's overall size and cost. The P66 series has an IP65 rating and is protected against dust and water.

- Conveyor technology (small conveyor belts, freight elevators, etc.)

- Packing and packaging machines (small labeling machines, small bag packaging machines, etc.)

- Special machines (mixing machines, kneading machines, textile machines, etc.)

- Pumps, compressors, fans

- Freight elevators

- Wood processing (automated lathes, saws, milling machines, etc.)

- Metalworking and processing (bending presses, welding machines, cutting machines, etc.)

- Holding brake control

- Current limiting

- Torque limiting

- Automatic catching of rotating loads with speed detection (catching on the fly)

- Undervoltage management

- Configurable safety functions

Power range for 50 to 60 Hz (kW) mains supply | |

|---|---|

1-phase, 200 to 240 V (kW) | 0.18 to 2.2 |

3-phase, 200 to 240 V (kW) | 0.18 to 15 |

3-phase, 380 to 500 V (kW) | 0.37 to 15 |

3-phase, 525 to 600 V (kW) | 0.75 to 15 |

Drive | |||

|---|---|---|---|

Output frequency | 0.1 to 599 Hz | ||

Control type | Induction motor | Sensorless vector control: Sensorless slip control: | |

Synchronous motor | Sensorless vector control: | ||

Short-term overload torque | 170 to 200% of the nominal motor torque | ||

Functions | ||

|---|---|---|

Safety functions | Integrated | STO (Safe Torque Off), SLS (Safe Limited Speed), SS1 (Safe Stop 1) |

Number of inputs/outputs | Analog inputs | 3 |

Logic inputs | 6 | |

Analog outputs | 1 | |

Logic outputs | 1 | |

Relay outputs | 2 | |

Communication | ||

|---|---|---|

Network interfaces | Interface cards | POWERLINK, X2X Link |

Integrated | CANopen | |

ACOPOSinverter P76 frequency inverters include various drive profiles for three-phase induction motors and synchronous motors with a power supply from 200 to 500 V and a power rating from 0.18 to 15 kW. The combination of an ACOPOSinverter P76 and an encoderless synchronous motor is very compact, contributing significantly to the reduction of the machine's overall size and cost.

- Conveyor technology (small conveyor belts, freight elevators, etc.)

- Packing and packaging machines (small labeling machines, small bag packaging machines, etc.)

- Special machines (mixing machines, kneading machines, textile machines, etc.)

- Pumps, compressors, fans

- Freight elevators

- Wood processing (automated lathes, saws, milling machines, etc.)

- Metalworking and processing (bending presses, welding machines, cutting machines, etc.)

Power range for 50 to 60 Hz (kW) mains supply | |

|---|---|

1-phase, 200 to 240 V (kW) | 0.18 to 2.2 |

3-phase, 380 to 500 V (kW) | 0.37 to 15 |

Drive | ||

|---|---|---|

Output frequency | 0.1 to 599 Hz | |

Control type | Induction motor | Sensorless vector control: Sensorless slip control: |

Synchronous motor | Sensorless vector control: | |

Short-term overload torque | 170 to 200% of the nominal motor torque | |

Functions | ||

|---|---|---|

Safety functions | Integrated | STO (Safe Torque Off), SLS (Safe Limited Speed), SS1 (Safe Stop 1) |

Number of inputs/outputs | Analog inputs | 3 |

Logic inputs | 6 | |

Analog outputs | 1 | |

Logic outputs | 1 | |

Relay outputs | 2 | |

Communication | ||

|---|---|---|

Network interfaces | Interface cards | POWERLINK |

ACOPOSinverter P86 frequency inverters include various drive profiles for three-phase induction motors and synchronous motors with a power supply from 380 to 480 V and a power rating from 0.75 to 75 kW. The combination of an ACOPOSinverter P86 and an encoderless synchronous motor is very compact, contributing significantly to the reduction of the machine's overall size and cost.

- Conveyor technology (small conveyor belts, freight elevators, etc.)

- Packing and packaging machines (small labeling machines, small bag packaging machines, etc.)

- Special machines (mixing machines, kneading machines, textile machines, etc.)

- Pumps, compressors, fans

- Freight elevators

- Wood processing (automated lathes, saws, milling machines, etc.)

- Metalworking and processing (bending presses, welding machines, cutting machines, etc.)

Power range for 50 to 60 Hz (kW) mains supply | |

|---|---|

3-phase, 380 to 480 V (kW) | 0.75 to 75 |

Drive | ||

|---|---|---|

Output frequency | 0.1 to 599 Hz | |

Control type | Induction motor | Vector control with speed sensor: Sensorless vector control: Sensorless slip control: |

Synchronous motor | Vector control with speed sensor: Sensorless vector control: | |

Short-term overload torque | 0.75 to 22 kW: 220% | |

Functions | ||

|---|---|---|

Safety functions | Integrated | STO (Safe Torque Off), two-channel |

Number of inputs/outputs | Analog inputs | 0.75 to 22 kW: 2 |

Logic inputs | 0.75 to 22 kW: 5 + 2 | |

Analog outputs | 0.75 to 22 kW: 1 | |

Logic outputs | 0.75 to 22 kW: 2 | |

Relay outputs | 0.75 to 22 kW: 2 | |

Communication | ||

|---|---|---|

Network interfaces | Interface cards | POWERLINK |

Encoder interfaces | Interface cards | ABR, EnDat 2.2, SSI SinCos, HIPERFACE, resolver, HTL |

Integrated | 0.75 to 22 kW: ABR, SinCos | |

ACOPOSinverter P96 frequency inverters include various drive profiles for three-phase induction motors and synchronous motors with a power supply from 380 to 480 V and a power rating from 0.75 to 110 kW.

Power range for 50 to 60 Hz (kW) mains supply | |

|---|---|

3-phase, 380 to 480 V (kW) | 0.75 to 110 |

Drive | ||

|---|---|---|

Output frequency | 0 to 500 Hz | |

Control type | Induction motors | Direct Torque Control (DTC) Motor control in open and closed control loop |

Functions | ||

|---|---|---|

Safety functions | Integrated | STO (Safe Torque Off), two-channel |

Number of inputs/outputs | Analog inputs | 2 |

Logic inputs | Max. 8 (6 + 2 configurable I/Os) | |

Analog outputs | 2 | |

Logic outputs | Max. 2 (2 configurable I/Os) | |

Relay outputs | 3 | |

Communication | ||

|---|---|---|

Network interfaces | Interface cards | POWERLINK |

Encoder interfaces | Interface cards | A/B, resolver A/B, HTL EnDat / HIPERFACE / SSI / A/B / SinCos |