Innovative drives with an exceptionally small footprint

With the ACOPOS P3, B&R is setting new standards for motion control. This 3-axis servo drive offers a power density of 4 amps per liter, making it one of the most efficient servo drives with integrated safety functions on the market. It also offers unrivaled dynamics and precision, with a sampling time of just 50 µs for the entire controller cascade.

More than ever, machine and plant manufacturers are confronted with demands for higher productivity and increased availability. At the same time, the manufacturing costs for the production machines need to be reduced. The new generation of servo drives from B&R meets this challenge.

Servo drives (Single Axis Modules)

Servo drives, SafeMOTION (single-axis modules)

Servo drives (two-axis modules)

Servo drives, SafeMOTION (two-axis modules)

Servo drives (three-axis modules)

Servo drives, SafeMOTION (three-axis modules)

Passive line filter

Plug-in modules

Adapter cables

Cables (for use in cable drag chains)

Cables (cannot be used in cable drag chains)

Cable extensions

Accessories

Documentation

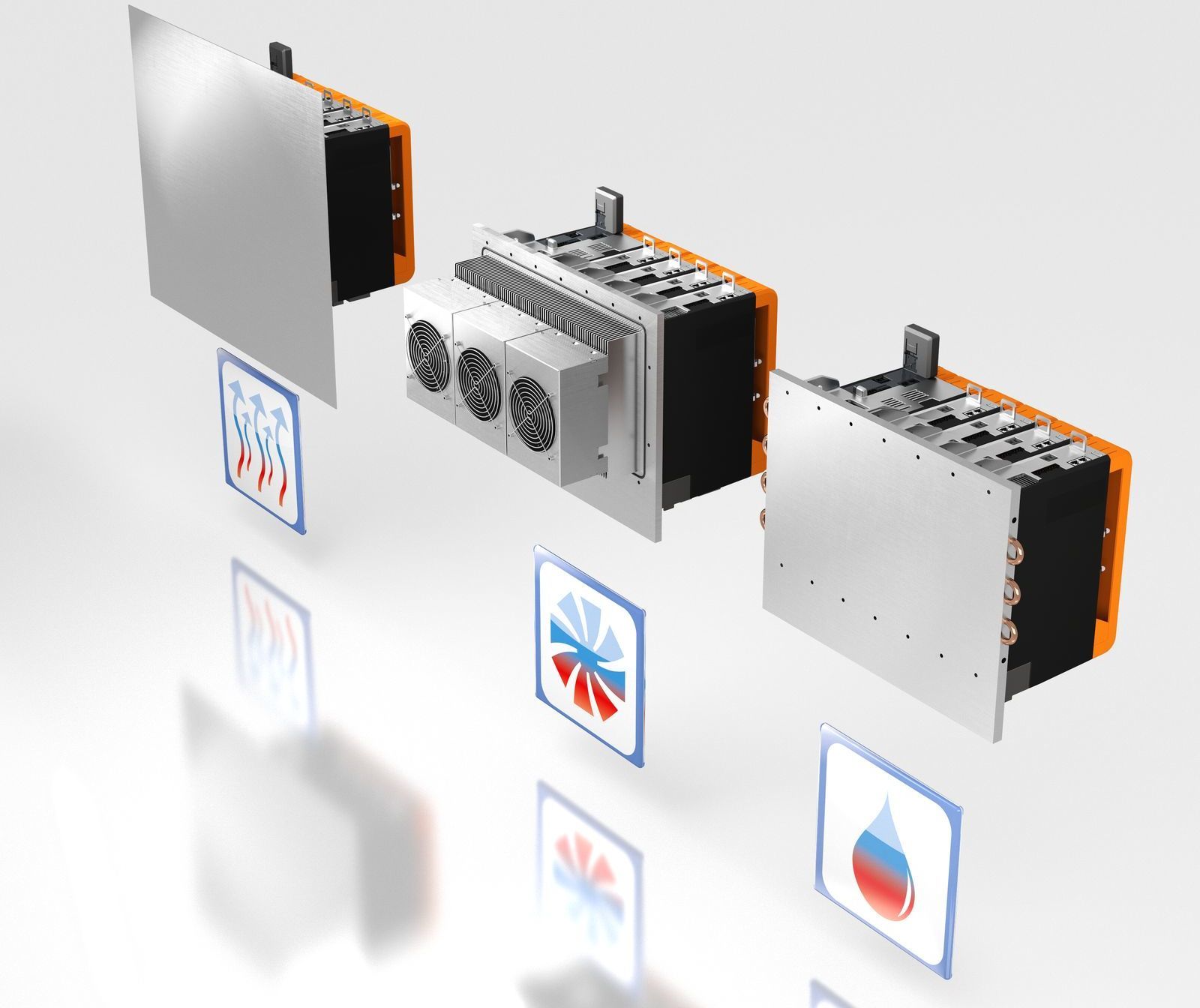

Modular cooling concept for ACOPOS P3

The ACOPOS P3 servo drive is now also available with feed-through heat sink or cold plate cooling. This reduces the use of fans and air conditioners in the control cabinet or, ideally, eliminates them altogether. Operation and maintenance costs are reduced.

- Highlights

- No additional maintenance required

- No additional fans in the control cabinet

- The right solution for every machine

System designers can now choose between the following cooling variants for the ACOPOS P3:

Wall mounting

With conventional wall mounting, heat dissipates via the air inside the control cabinet. This solution is optimal for a small number of axes with low power.

Pass-through mounting

With a large number of axes in all power ranges, pass-through mounting is more suitable. Based on a push-through heat sink with IP65 protection, the heat loss is dissipated directly to the ambient air outside the control cabinet. Costly cooling of the control cabinet itself is not necessary.

Cold plate mounting

This method utilizes a water-cooled cold plate. Virtually all heat loss from the devices is transferred to the coolant. This type of cooling is suitable for a large number of axes in all power ranges. It requires the machine to have its own cooling circuit.

69% smaller footprint and optimal power density

The ACOPOS P3 is available as a 1-, 2- or 3-axis system. It covers a power range from 0.6 to 18 kW or 1.6 to 44 amps. The housing of the 3-axis drive is as compact as a conventional 1-axis drive. Space consumption in the control cabinet is reduced by 69%. In addition, an integrated digital multi-encoder interface is available to the user for each axis.