The cost-effective alternative to the premium series

Standard series planetary gearboxes are the ideal solution for applications that do not require an extremely low level of backlash or IP65 protection. Typical applications for these gearboxes include those with high speeds and acceleration values as well as toothed belt or rack applications.

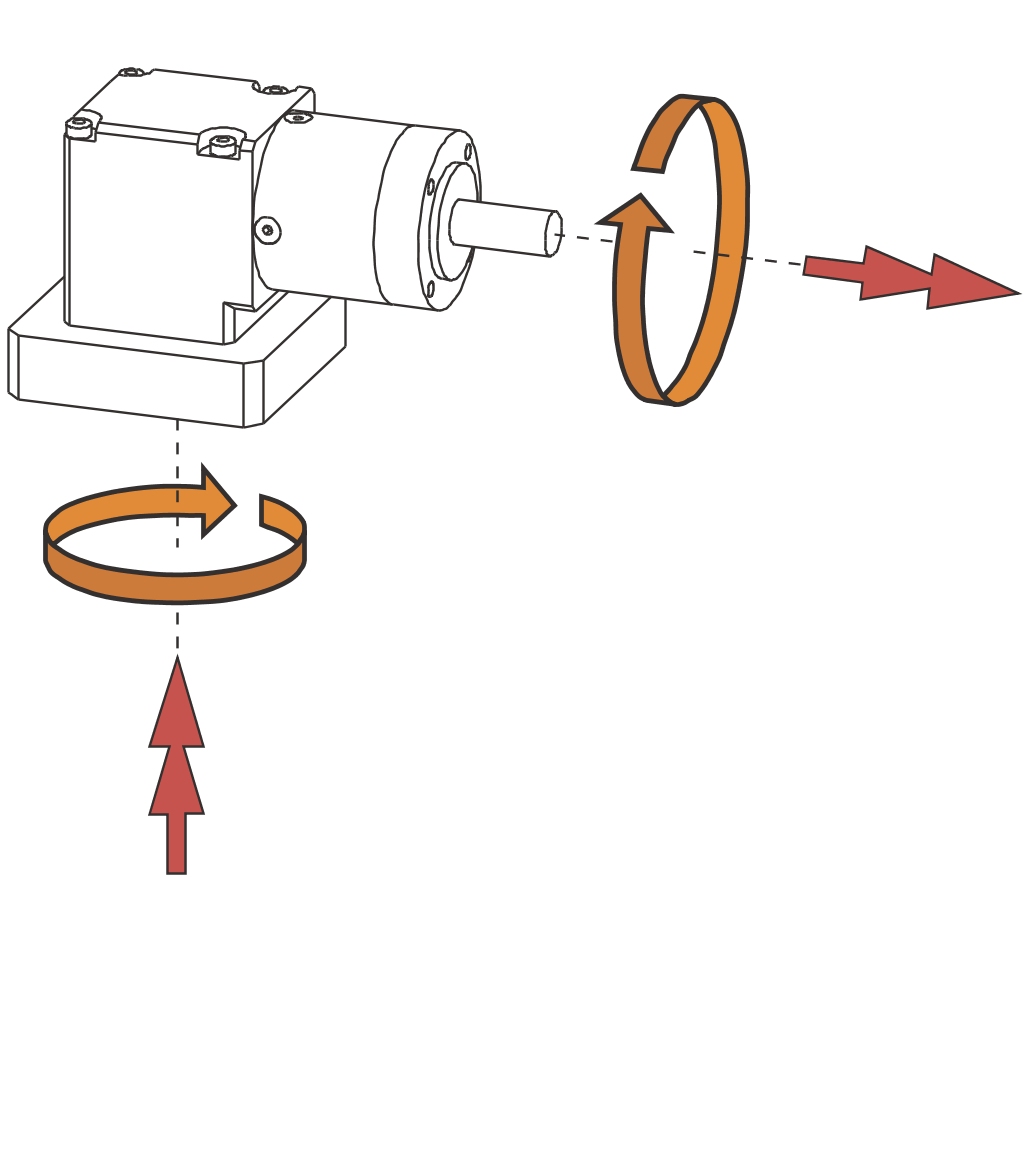

In combination with honed sun and planets, the straight-toothed and fully hardened toothing guarantee high output torque and high-precision positioning. The unique building block principle used with this series makes it possible to handle all output geometries established on the market in the area of coaxial planetary gearboxes. The standard series gearboxes are available as angular planetary gearboxes, planetary gearboxes with output flange and coaxial planetary gearboxes.

Planetary gearboxes with output shaft 8GP

Planetary gearboxes with output flange 8GF

Angular planetary gearboxes 8GA

Documentation

One-of-a-kind building block principle for planetary gearboxes

The standard gearboxes are single-stage for gear ratios i= 3, 4, 5, 7, 8 and 10 and have ≤8 - ≤15 arcmin backlash. In addition, these gearboxes are also offered in two-stage or three-stage designs. At the top of the product line, the premium series provides backlash ≤ 1 arcmin as an option paired with high output torques. B&R gearboxes from the standard series give you the possibility to choose between all output geometries established on the market in the area of coaxial planetary gearboxes.

- This enables B&R to supply gearboxes for existing applications without having to make changes to the machine.

With the 8GP55 series, you are also able to combine the output bearings and the output geometry of the 8GP60 premium series in combination with the torsional play of the standard series for applications that do not require extremely reduced backlash. This makes it possible to handle high radial and axial forces in a cost-efficient manner.

- In applications where the backlash of the standard series is sufficient, this offers a cost-optimized solution for implementing higher bearing forces.

Additional information

Standard planetary gearboxes

Premium planetary gearboxes

8G - Order key

Downloads

Online tools

CAD configurator For motors and gearboxes. Our CAD application allows you to access 2D/3D CAD data in many different formats.

Standard planetary gearboxes – 3 types

Standard planetary gearboxes – 3 types

8GP40

Planetary gearboxes

With output shaft

Series 40

8GP45

Planetary gearboxes

With output shaft

Series 45

8GP50

Planetary gearboxes

With output shaft

Series 50

8GP55

Planetary gearboxes

With output shaft

Series 55

8GP40 | 8GP45 | 8GP50 | 8GP55 | |

|---|---|---|---|---|

Class | Standard | |||

Size | 040, 060, 080, 120 | 067, 089, 121 | 050, 070, 090, 120, 155 | 60, 80, 120 |

Toothing type | Straight | |||

Protection | IP54 | IP65 | ||

Backlash [arcmin]: 1-stage 2-stage 3-stage | ≤7 - ≤15 ≤12 - ≤19 ≤14 - ≤22 | ≤8 - ≤12 ≤12 - ≤15 ≤14 - ≤18 | ≤8 - ≤15 ≤12 - ≤19 --- | ≤8 - ≤12 ≤12 - ≤15 --- |

Gear ratio: 1-stage 2-stage 3-stage | 3 - 10 9 - 100 60 - 512 | 3 - 10 9 - 100 60 - 512 | 3 - 10 9 - 100 --- | 3 - 10 9 - 100 --- |

Nominal output torque [Nm] | 5 - 260 | 15 - 260 | 5 - 460 | 15 - 260 |

Radial load 20,000 h [N] Refers to the center of the output shaft. Values refer to drive shaft speed n2 = 100 min-1 and application factor KA = 1 as well as S1 operation for electrical machines and T = 30°C. Depends on the diameter of the respective motor shaft. | 200 - 1750 | 900 - 2950 | 800 - 5200 | 3200 - 6000 |

Axial load 20,000 h [N] Refers to the center of the output shaft. Values refer to drive shaft speed n2 = 100 min-1 and application factor KA = 1 as well as S1 operation for electrical machines and T = 30°C. Depends on the diameter of the respective motor shaft. | 200 - 2500 | 1000 - 2500 | 1000 - 7000 | 4400 - 8000 |

Smooth shaft Keyed shaft Toothed shaft | Optionally available Standard --- | Optionally available Standard --- | Optionally available Standard --- | Standard Optionally available --- |

8GF40

Planetary gearboxes

With output flange

Series 40

8GF40 | |

|---|---|

Class | Standard |

Size | 064, 090, 110 |

Toothing type | Straight |

Protection | IP54 |

Backlash [arcmin]: 1-stage 2-stage 3-stage | ≤8 - ≤12 ≤12 - ≤16 --- |

Gear ratio: 1-stage 2-stage 3-stage | 3 - 10 9 - 100 --- |

Nominal output torque [Nm] | 15 - 260 |

Radial load 20,000 h [N] Refers to the center of the output shaft. Values refer to drive shaft speed n2 = 100 min-1 and application factor KA = 1 as well as S1 operation for electrical machines and T = 30°C. Depends on the diameter of the respective motor shaft. | 550 - 2400 |

Axial load 20,000 h [N] Refers to the center of the output shaft. Values refer to drive shaft speed n2 = 100 min-1 and application factor KA = 1 as well as S1 operation for electrical machines and T = 30°C. Depends on the diameter of the respective motor shaft. | 1200 - 3300 |

Drive flange | Standard |

8GA40

Angular planetary gearbox with output shaft

Series 40

8GA45

Angular planetary gearbox with output shaft

Series 45

8GA50

Angular planetary gearbox with output shaft

Series 50

8GA55

Angular planetary gearbox with output shaft

Series 55

8GA40 | 8GA45 | 8GA50 | 8GA55 | |

|---|---|---|---|---|

Class | Standard | |||

Size | 040, 060, 080, 120 | 067, 089, 121 | 050, 070, 090, 120 | 064, 090, 110 |

Toothing type | Straight | |||

Protection | IP54 | |||

Backlash [arcmin]: 1-stage 2-stage 3-stage | ≤12 - ≤21 ≤16 - ≤25 ≤18 - ≤28 | ≤12- ≤14 ≤16 - ≤18 ≤18 - ≤20 | ≤12 - ≤21 ≤16 - ≤25 --- | ≤12 - ≤17 ≤14 - ≤19 --- |

Gear ratio: 1-stage 2-stage 3-stage | 3 - 10 9 - 100 60 - 512 | 3 - 10 9 - 100 60 - 512 | 3 - 10 9 - 100 --- | 3 - 10 9 - 100 --- |

Nominal output torque [Nm] | 4.5 - 260 | 38 - 260 | 4.5 - 195 | 14 - 260 |

Radial load 20,000 h [N] Refers to the center of the output shaft. Values refer to drive shaft speed n2 = 100 min-1 and application factor KA = 1 as well as S1 operation for electrical machines and T = 30°C. Depends on the diameter of the respective motor shaft. | 200 - 1750 | 900 - 2950 | 800 - 2500 | 550 - 2400 |

Axial load 20,000 h [N] Refers to the center of the output shaft. Values refer to drive shaft speed n2 = 100 min-1 and application factor KA = 1 as well as S1 operation for electrical machines and T = 30°C. Depends on the diameter of the respective motor shaft. | 200 - 2500 | 1000 - 2500 | 1000 - 4000 | 1200 - 3300 |

Smooth shaft Keyed shaft Drive flange | Optionally available Standard --- | Optionally available Standard --- | Optionally available Standard --- | --- --- Standard |

Direction of rotation