Efficient and sustainable printing: B&R shapes the future of the printing industry

The increasing demand for individualized print media, geared towards selective and target group-oriented marketing, is a clear trend. In this context, small print runs are becoming increasingly important. B&R understands the challenges facing the printing industry: The need for efficient and flexible production with smaller batch sizes and the transition to sustainable printing processes by minimizing waste or increasing energy efficiency.

As an innovative solution provider, B&R focuses on adaptive and sustainable processes and implements end-to-end automation. B&R enables maximum flexibility in production to minimize downtime and setup times, reduce waste and efficiently network machines. B&R customers design personalized print not only at the highest level, but also efficiently and with increased sustainability. Here, printing is not only personalized, but also intelligent, efficient and environmentally friendly.

Digital printing

Individualization paired with outstanding print quality at high printing speeds – that's digital printing based on integrated automation and precise drive technology from B&R. The connectivity of the controllers used makes it easy to implement conventional printing units or downstream finishing processes.

Conventional printing

With B&R, customers experience printing solutions for long runs and impressive speeds. Exact registration mark detection, precise synchronization of the axes and fast reaction to deviations are the hallmarks of B&R's proven drive technology. Efficient printing with minimal waste – B&R unites quality and speed on every printed page.

Print processing

B&R goes beyond the printing process and enhances printed products. A wide range of options such as coating, embossing and bookbinding turn a printed item into a complete product. B&R simplifies the workflow through extensive digital integration and enables open communication with higher-level systems. This not only increases production quality, but also takes efficiency to a new level.

Adaptive, efficient and sustainable – next-generation printing

Plug & Print

B&R enables customized modularization of printing presses with a variety of centralized and decentralized automation components as well as software modularization in Automation Studio. Commissioning takes place without changing the software. OPC UA FX automatically identifies machine modules and determines their position in the network, regardless of whether they have their own controller. This enables automatic configuration without the need for manual settings.

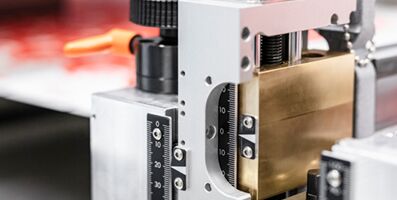

High-precision drive technology

B&R offers high-quality servo drives such as ACOPOS P3, ACOPOSmulti, ACOPOSremote and ACOPOSmotor for precise control and outstanding product quality. The flexible and scalable solutions cover a wide performance range as well as centralized and decentralized machine concepts. Frequency inverters and drive systems for controlling DC motors and stepper motors complete the product range.

Integrated safety technology

With B&R, companies can easily and flexibly implement safety solutions in accordance with EN 1010 and EN 13849. Reduced safety distance requirements allow for more compact machine designs. With response times that are ten times faster than conventional solutions, B&R safety technology enables uninterrupted production at reduced speed in the event of a safety incident to avoid costly machine downtime.

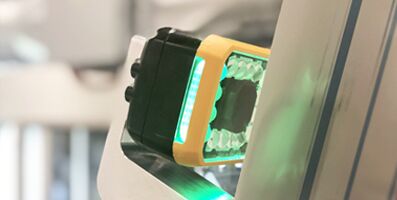

Registration mark detection

The exact positioning and alignment of the printed image is crucial for print quality and further processing. B&R makes this possible with precise detection of all common registration marks, even at high speeds. Simple integration and fast control cycles are achieved by connecting directly to the servo drive or via a fieldbus with direct cross-communication.

Energy and resource efficiency

Cost-effective print media production requires efficient use of energy and resources. This is achieved through regenerative drive systems, automatic PWM adjustment and highly efficient servo motors. Energy measurement at various levels supports systematic energy management. In addition, B&R's high-speed register control enables a significant reduction in waste on conventional presses.

Success stories from the field – B&R user reports

The future of flexo

Nilpeter and B&R have developed a revolutionary vision system. Learn how it simultaneously reduces waste, improves quality and minimizes labor. The system sets new standards in color register accuracy, even with flexible materials. Microsecond synchronization ensures consistent print quality and makes the system unique.

Holding all cards for maximum productivity

Modern ID cards and smart cards with RFID or microchips provide security, fast payment and easy access to services – indispensable in our digital world. Melzer Maschinenbau GmbH, a leading manufacturer of smart cards and labels, relies on B&R technology for maximum precision and speed. Read how B&R's ACOPOS drive systems and first-class support keep Melzer at the forefront of ID card system manufacturers.

Innovation for high performance

Against the backdrop of ever-increasing costs, Berhalter in Widnau, Switzerland, has developed a machine that achieves 25% higher output at lower production costs thanks to revolutionary technologies such as real-time stroke correction and digital drive systems. The key partner in this development was B&R, whose reACTION technology contributed significantly to the success. In less than two years, a machine was created that sets new standards with 500 cycles per minute and intelligent servo axes. The full story.

B&R revolutionizes the printing industry with advanced drive technology

Support for the creation of sustainable printing solutions

Why is OPC UA FX ideal for modular printing presses?

Why is OPC UA FX ideal for modular printing presses?

OPC UA FX is the ideal network for modular printing machines. First, it combines the best features of today's fieldbuses. Gigabit Ethernet with Time-Sensitive Networking (TSN) is used at the network level. This guarantees full topology freedom, sufficient bandwidth for future applications and deterministic data transmission, which is essential for the synchronization of drive axes, for example. Multi-vendor interoperability ensures seamless communication between automation components from different manufacturers. This also includes devices used for functional safety.

The most important addition in terms of modularization is the integrated topology detection, which can be used to determine the physical topology of the network. Newly connected modules and their position in the machine can be determined automatically. This enables adaptive machine software as well as flexible adaptation and integration of new modules to changing requirements.

The vertical extension of OPC UA to the field level ensures complete consistency of semantic data from the sensor to the cloud. This facilitates integration into higher-level production and information systems. In this context, it is particularly important that communication encryption, authentication and authorization are also integral components at the field level. This means that printing machines also meet increasing safety requirements.

How can the best print quality be achieved?

How can the best print quality be achieved?

B&R uses state-of-the-art servo drives with very fast and precise control to achieve the best print quality. The minimum sampling time is 50 µs for the entire controller cascade. Model predictive control compensates for motor cogging and periodic disturbances. This enables outstanding print quality and optimizes performance even under demanding conditions.

B&R's motion control technology fits seamlessly into its overall automation system – along with machine control, HMI and safety technology – to create a complete system solution. With ACOPOS P3, ACOPOSmulti, ACOPOSremote and ACOPOSmotor devices, you can take advantage of flexibility and scalability when designing your machine. This is the case with single or multi-axis drive systems, in the control cabinet or remotely and in a power range from 250 watts up to 122 kW.

How can I find the optimum solution for registration mark detection?

How can I find the optimum solution for registration mark detection?

From simple block marking for print processing to micrometer-precise detection of the smallest dot marks for offset printing. B&R offers the right solution for every application:

For moderate requirements, a digital contrast sensor connected either directly to the drive or via a NetTime module is sufficient. If the requirements increase, e.g. for register control, the X67BC8591.L12 in combination with an analog contrast sensor is recommended. The module's intelligent evaluation algorithms ensure high positioning accuracy at high path velocities, e.g. ±3 µm at 1,000 m/s. A B&R Smart Camera is the ideal solution for maximum flexibility and support for all common registration marks. It covers a wide range of requirements and offers maximum versatility.

Do you have any questions? – Talk to our industry expert.

More ways to contact B&R: Local partners and trade show dates

Find a partner near you

Take advantage of our global network for end customers.

In addition to more than 200 B&R subsidiaries in over 70 countries around the world, we have a global network of Value Providers. B&R Value Providers work seamlessly with B&R to bring our products and services to your location. They combine in-depth knowledge of B&R technology with a deep understanding of your local market.