Using wind power optimally and efficiently

Wind power is the use of air flow through wind turbines in order to generate electricity. Onshore wind power makes a significant contribution to the world's electricity supply. In the case of offshore wind power, one of the goals is to significantly reduce the cost of maintenance. What both concepts have in common is the requirement to align the wind turbine in order to be able to use wind power optimally and efficiently, while at the same time reducing the resulting mechanical stress.

Conventional concepts with disadvantages

Conventional concepts with motors operated directly from the grid have disadvantages related to the technology used. Unwanted loads caused by jerky start-up processes lead to increased mechanical wear. Especially in the offshore sector with tower head masses of up to 500 tons, high mechanical wear leads to failures and the need to service the turbines. In addition, the mechanical load is increased because the nacelle is held in place by a hydraulic brake. These challenges can be overcome using active or passive approaches. Passive systems – such as wind vanes – have been used in the past for smaller installations.

Optimization of yaw control

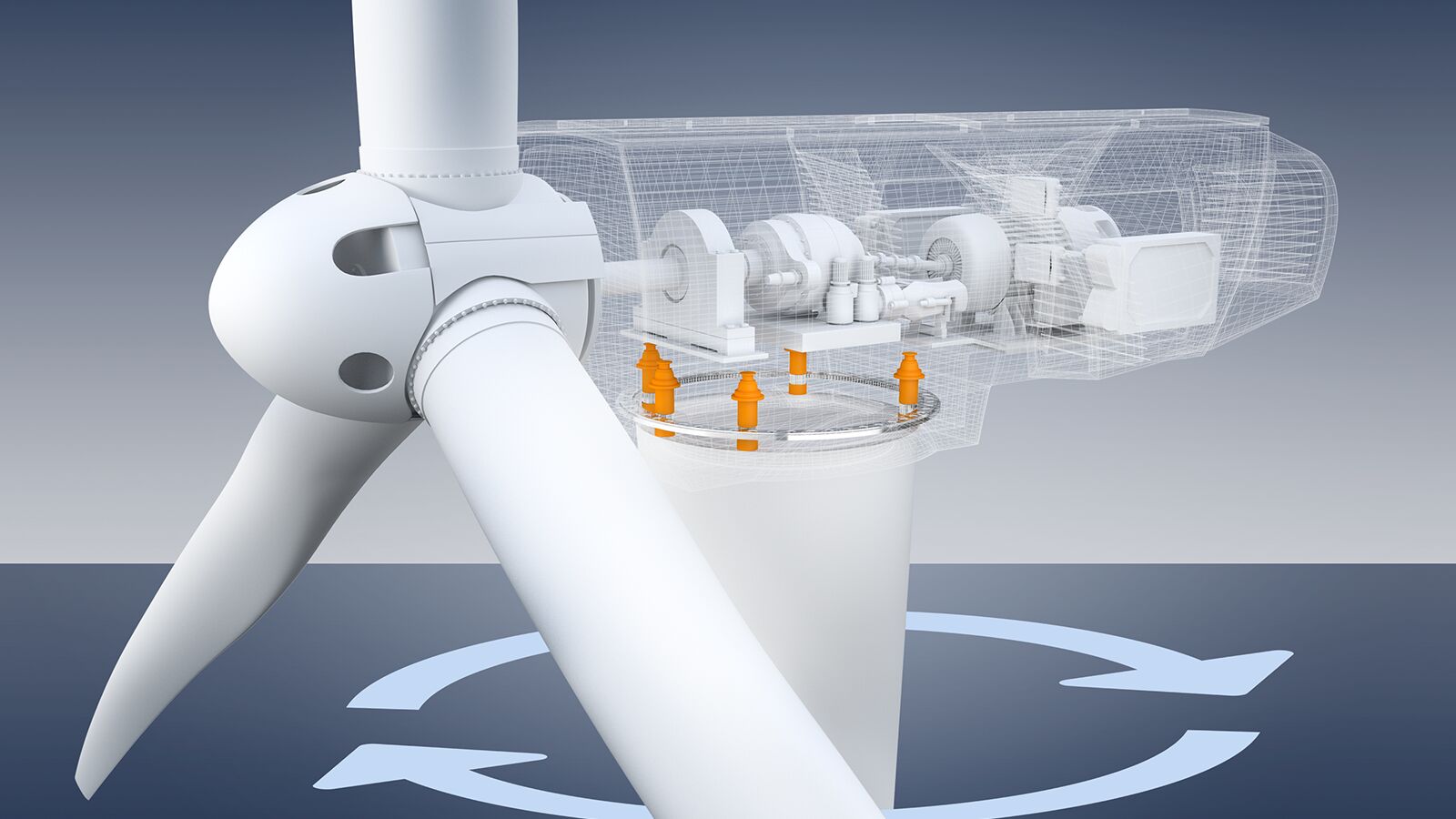

Modern wind turbines are automatically tracked by active systems with multiple motors – so-called yaw control. The motors are typically controlled by a soft starter or a frequency inverter. Intelligent servo drives allow yaw control to be optimized. Intelligent torque control, for instance, can reduce the levels of torque experienced by mechanical components. Then you have backlash compensation, which prevents the impacts that otherwise occur between gear teeth when the turbine changes direction. Since wear is greatly reduced, the position of the nacelle can be readjusted more often – yield and availability increase. Furthermore, redundancy concepts ensure safe operation – even if individual motors fail.

We know the requirements for wind turbines: Efficiency, sustainability, reliability, safety and connectivity

Precision control

State-of-the-art technologies ensure precise control of wind turbines. Every gust of wind is used optimally to achieve the highest energy yields. With B&R technology, wind turbines are always one step ahead.

Ecological efficiency

Every technology we use aims to maximize energy efficiency. This leads not only to higher yields, but also to more sustainable wind power concepts. A greener approach for a greener future.

Rugged reliability

Our solutions are designed to work continuously in the toughest conditions. Downtime and operating costs are drastically reduced, increasing the overall profitability of each system.

Maximum safety

The first priority is always safety. Integrated safety functions protect both on-site personnel and the equipment itself. In addition, innovations are continuously being developed to further increase this protection.

Digital integration

We are at the forefront of the digital revolution. By integrating IoT and Industry 4.0 concepts, data can be collected and analyzed, enabling processes to be continuously optimized. A smart approach for smart systems.

B&R technology developed for offshore

The ACOPOS P3 servo drive, specially developed for extreme sea conditions, controls up to 3 axes. Thanks to remote access possibilities, important drive parameters can be read out efficiently. The seawater-resistant design and first-class safety standards make it the first choice for offshore use.

Downloads, news and other resources

Robust hardware for electrical and hydraulic blade adjustment

The powerful X90 controller with integrated safety technology was specially developed for harsh environments. The control system is suitable for both electrical and hydraulic pitch systems on onshore and offshore wind turbines and can be used outside or inside control cabinets as required.

Increased availability with redundancy

B&R maximizes the reliability of the entire automation system by offering various redundancy options: Controller, network and power supply redundancy.

Proven safety solution for wind turbines

The safety system is fully and transparently integrated into the standard control system. B&R's extensive product portfolio makes it possible to find a cost-optimized safety solution for every application. In addition, customized error responses can be implemented.