Are you ready?

From the powertrain to the supply chain, the automotive industry is undergoing dramatic changes as the shift from combustion-powered to electric vehicles gains momentum. Particularly in the production of battery systems, car manufacturers and their suppliers find themselves confronted with a new set of challenges.

The capacity challenge –

Exponential growth: The race is on!

Demand for EV battery systems will skyrocket in the next few years. To keep up with exponential capacity growth, cycle times in battery cell production must be orders of magnitude faster than for traditional automotive components.

The price pressure challenge –

How to lower unit cost

Batteries account for around a third of electric vehicle cost and are currently produced at incredibly tight margins. To reduce unit costs, increasing production capacity is one part of the equation. The other is reducing energy consumption and increasing yield rates.

The quality challenge –

100% inline testing and traceability

Automotive parts have to comply with strict quality standards to guarantee safety and avoid costly recalls. On top of that, battery systems are more sensitive to contamination than traditional car parts. These problems are solvable enough on their own. The question is: how do you do it without slowing down?

The time-to-market challenge –

Ramp up faster without the risk

The combustion-electric transition is a steep curve. Government incentives and sustainability-conscious consumers are powerful catalysts, and battery production capacity will be hard pressed to keep up. In the race to get the latest battery systems to market, the winners will be those who make the most effective use of their development resources.

The future-proof challenge –

Build a factory to produce the unknown

How do you build a factory today that will still produce the quantities you need ten years from now? How do you build a factory today to produce battery technology that hasn't been invented yet?

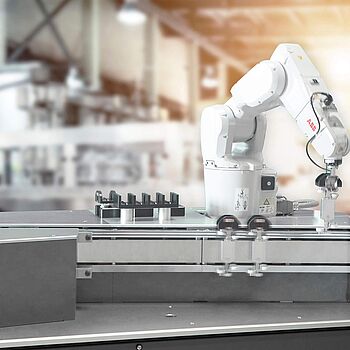

Solutions for your challenges

Key technologies for your needs

Let's talk batteries

Contact B&R's e-mobility specialist today!

Ronny Guber

battery@br-automation.com

Memberships

We are actively involved in shaping this market. Therefore, we are a member of the VDMA battery production department, the European Battery Alliance and the Batteryline.com expert community.

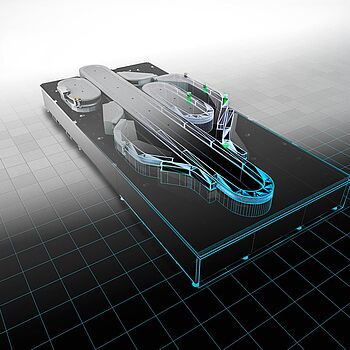

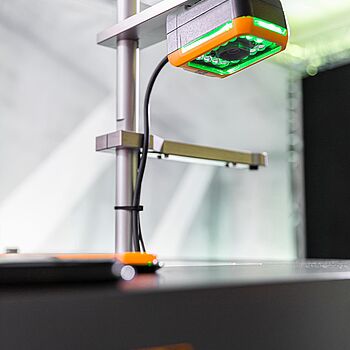

Area density measurement

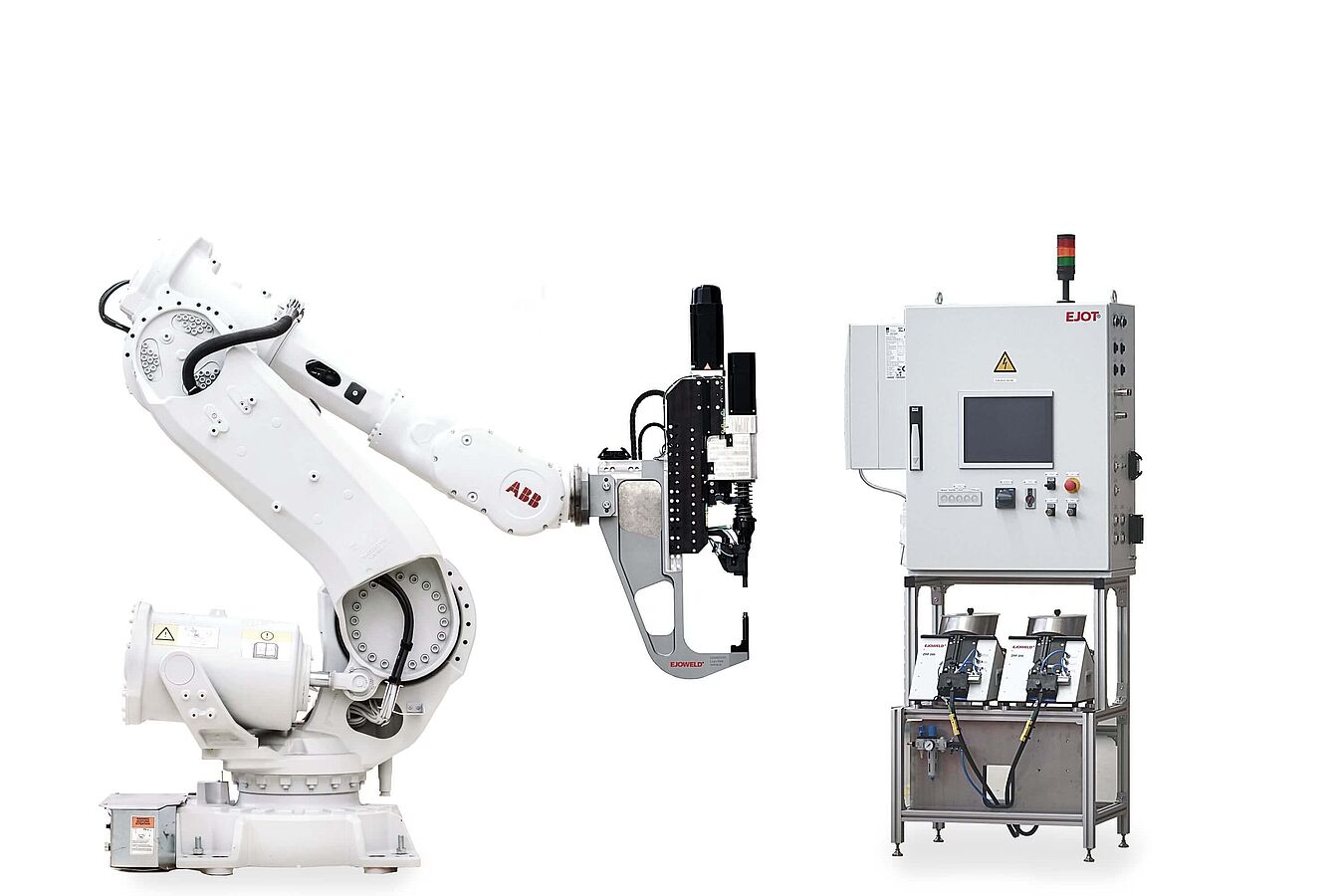

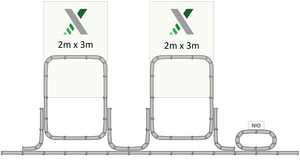

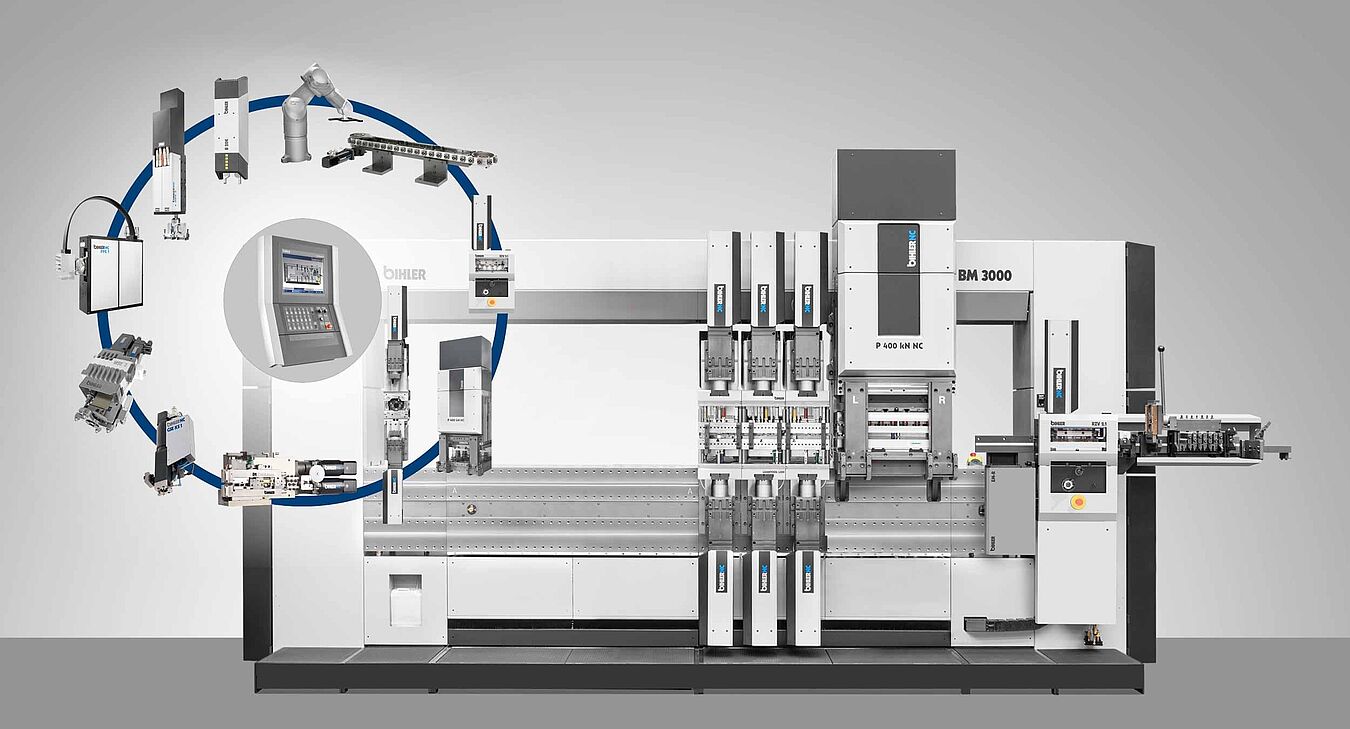

Busbar production

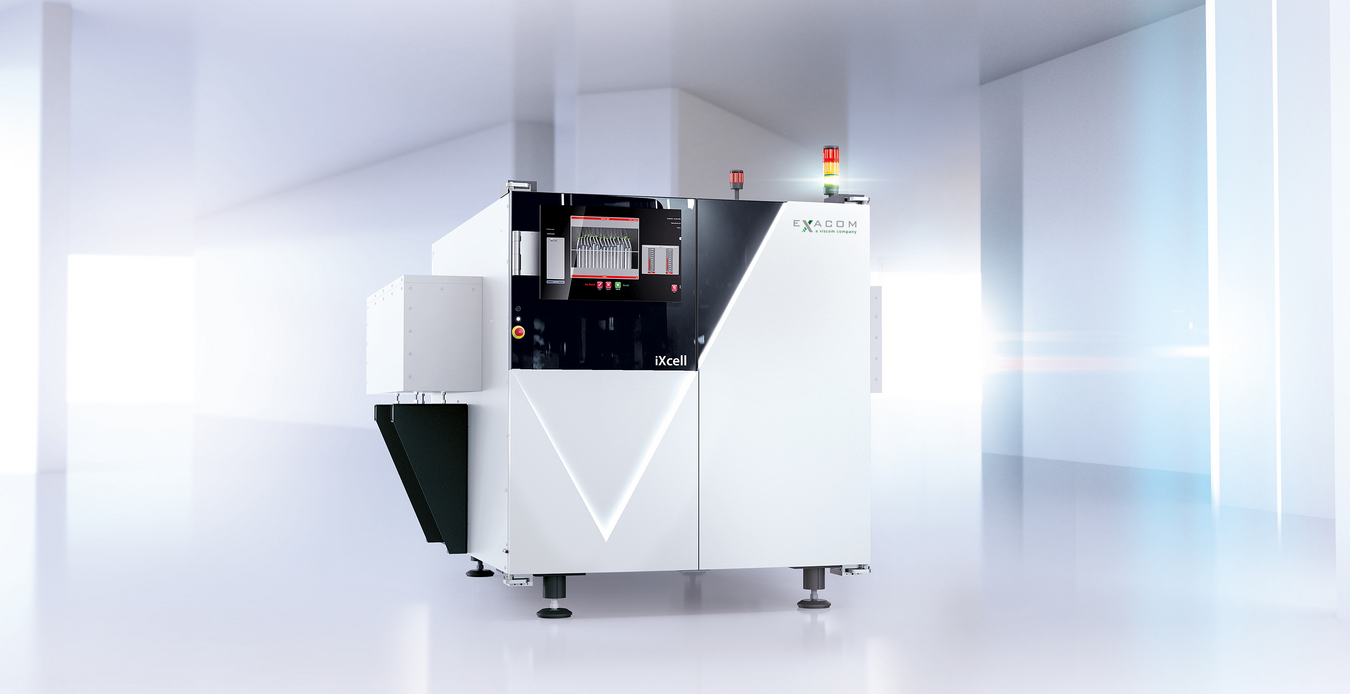

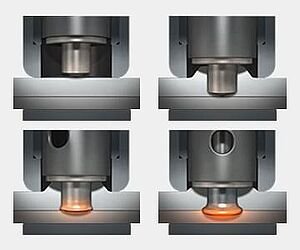

X-ray inspection