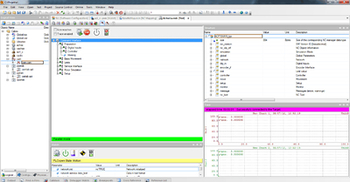

All B&R products are programmed in a uniform manner using B&R Automation Studio with the Windows look and feel. Complex drive solutions can be created after a short orientation period. Adding hardware components and program sections, as well as their configuration, is done in dialog boxes; this reduces project development times considerably.

Axis movements can be checked without programming using NC Test. All types of movements, ranging from point-to-point to gear functions, can be carried out interactively. The reaction of the axis can be seen online in the monitor window. The trace function records relevant drive data for clear evaluation.