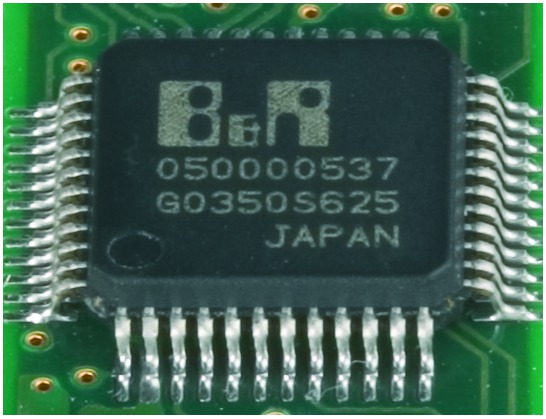

Each module in the ACOPOSmulti drive system can be uniquely identified using an embedded parameter chip. This makes it possible to identify each module on the network. This paves the way for automatic system configuration using the application program, which is of particular interest for many different machine types.

Consequently, not only ACOPOSmulti modules use this method of identification. B&R motors are also equipped with an embedded parameter chip. It contains all of the mechanical and electronic data relevant to the motor. This makes it possible for the application program to identify the entire power transmission system. The work-intensive and error-prone task of manually setting parameters is no longer necessary and start-up times are substantially reduced.

A simple comparison of the machine configuration when servicing the system helps to quickly diagnose faulty arrangements and minimizes costly downtimes.

The valuable information provided also allows you to draw conclusions about usage and possible errors.

Future compatibility ensured with embedded parameter chip

The unique identification of the ACOPOSmulti modules via embedded parameter chip meets the necessary demands when using systems in validated environments. It must be possible to identify each time a module is exchanged. Applications with these demands (e.g. FDA, GAMP, 21CFR11) are becoming more and more common.