8D1 | b | c | d | . | e | f | g | h | i | j | k | ll | - | m |

Construction type | ||||||||||||||||||||||||||||||||

Size | ||||||||||||||||||||||||||||||||

Length | ||||||||||||||||||||||||||||||||

Motor encoder system / Electronics option | ||||||||||||||||||||||||||||||||

Nominal speed | ||||||||||||||||||||||||||||||||

Motor options | ||||||||||||||||||||||||||||||||

Gearbox | ||||||||||||||||||||||||||||||||

Gearbox size | ||||||||||||||||||||||||||||||||

Gear ratio | ||||||||||||||||||||||||||||||||

Gearbox options | ||||||||||||||||||||||||||||||||

Special options | ||||||||||||||||||||||||||||||||

Version | ||||||||||||||||||||||||||||||||

Order keys only provide information about possible combinations in exceptional cases.

Information about possible combinations is available in the CAD configurator.

Additional information

ACOPOSmotor Compact

8D1 - General motor data

8D1 - Order key

Construction type (b)

Construction type (b)

8D1 | b | c | d | . | e | f | g | h | i | j | k | ll | - | m |

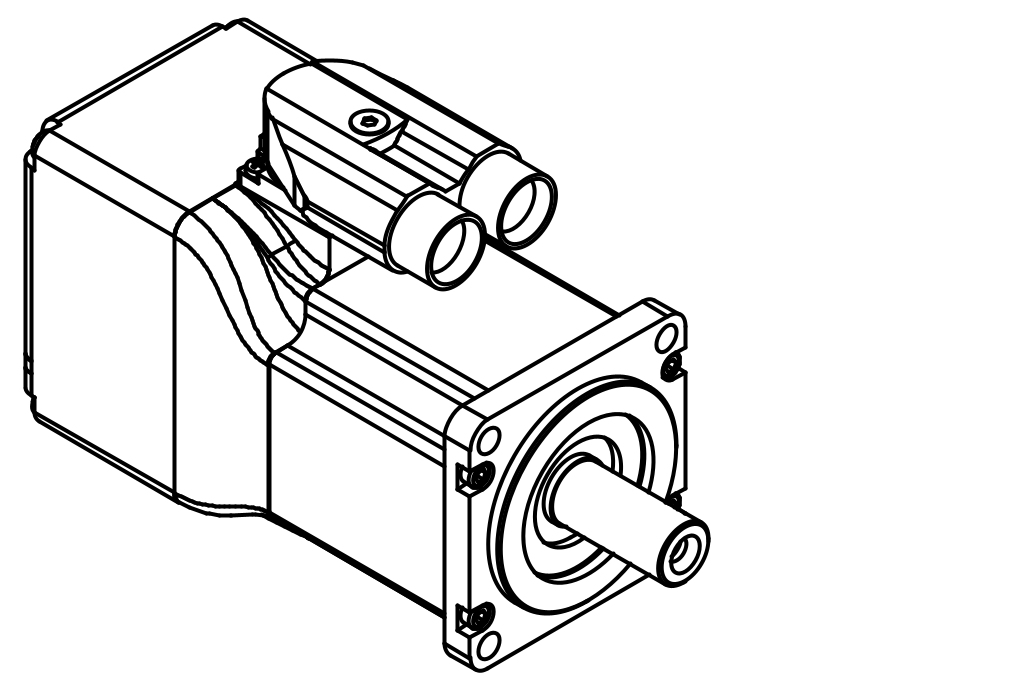

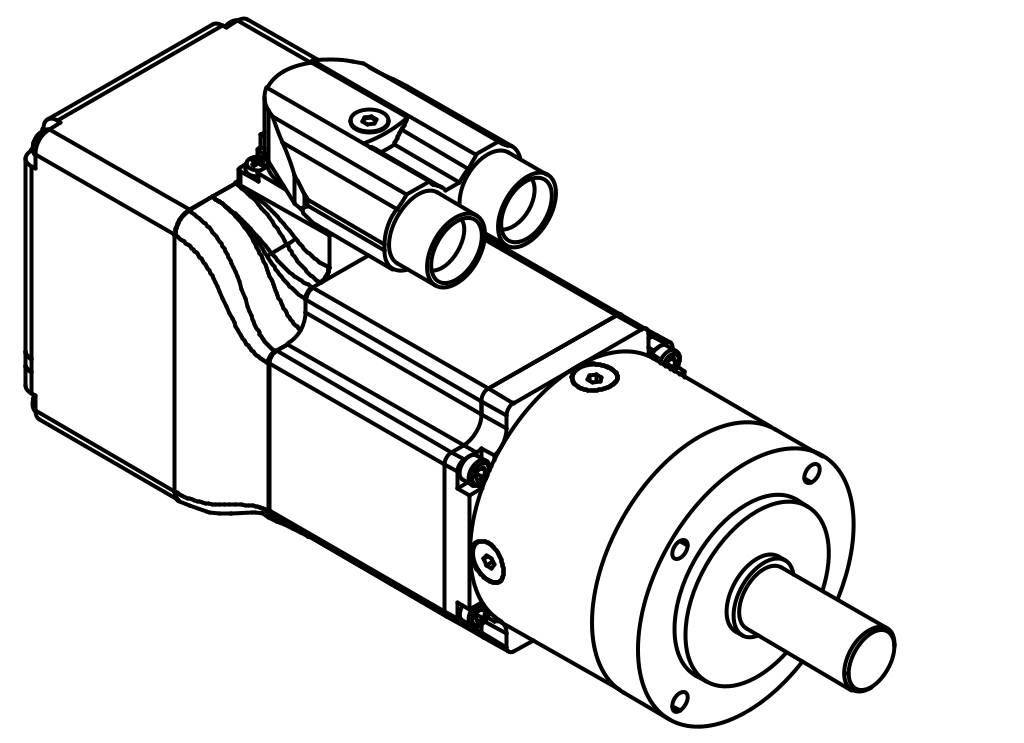

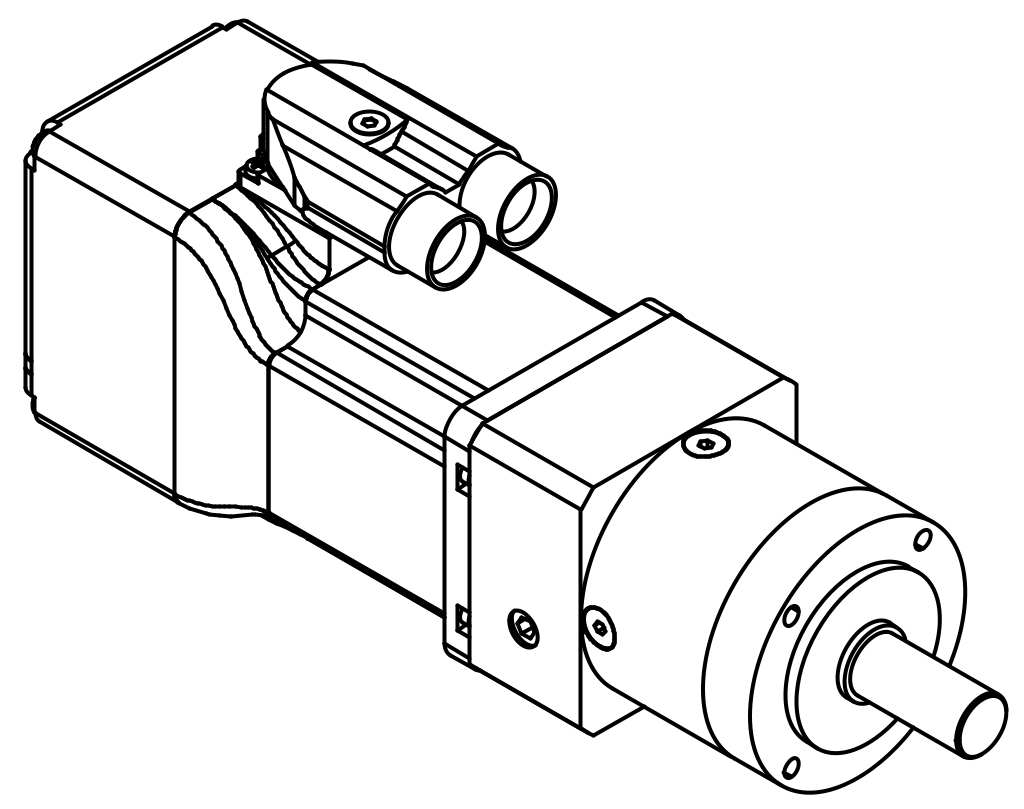

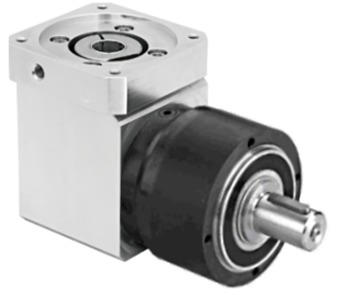

ACOPOSmotor Compact modules are available in 3 different construction types (8D1A, 8D1B and 8D1C).

The construction type is differentiated by a letter (b) in the order number.

Construction type (b) | Cooling type | Connection type | Gearbox | Order code |

|---|---|---|---|---|

8D1A | Self-cooling | Connector | Without gearbox | 8D1Acd.efg000000-1 |

8D1B | Yes (direct mounting) | 8D1Bcd.efghijkll-1 | ||

8D1C | Yes (flanged) | 8D1Ccd.efghijkll-1 |

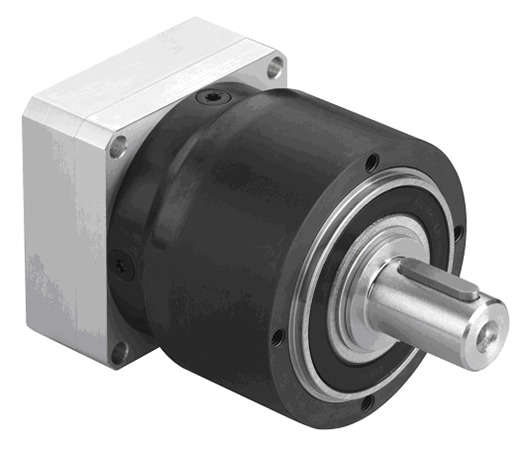

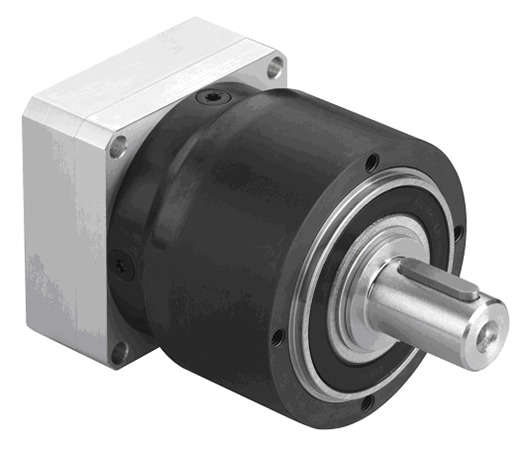

8D1A

|

|

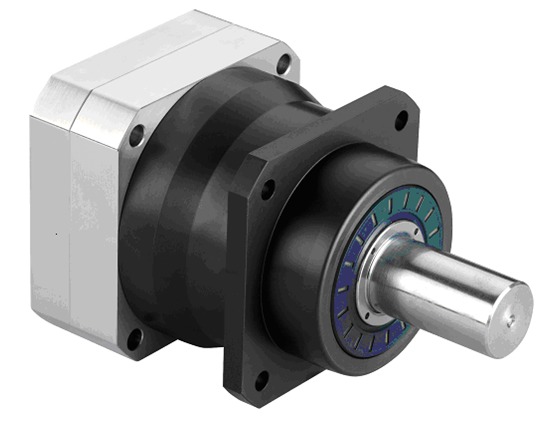

8D1B

|

|

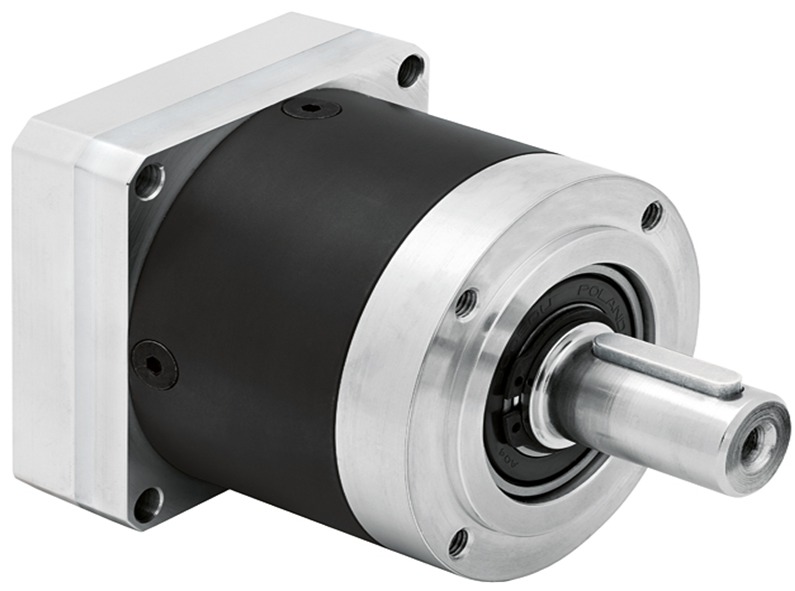

8D1C

|

|

Size (c)

Size (c)

8D1 | b | c | d | . | e | f | g | h | i | j | k | ll | - | m |

8D1 | b | c | d | . | e | f | g | h | i | j | k | ll | - | 1 | Order key |

ACOPOSmotor Compact modules are available in various sizes.

The size is differentiated by a digit (c) in the order number. The larger this digit, the larger the flange dimensions and power data of the respective ACOPOSmotor Compact module.

Sizes (c) | |

|---|---|

8D1x2 | |

8D1A | Yes |

8D1B | Yes |

8D1C | Yes |

Sizes (c) | |

|---|---|

8D1x3 | |

8D1A | Yes |

8D1B | Yes |

8D1C | Yes |

Length (d)

Length (d)

8D1 | b | c | d | . | e | f | g | h | i | j | k | ll | - | m |

ACOPOSmotor Compact modules are available in various lengths. These differ in the power data with identical flange dimensions. The different lengths are differentiated by a digit (d) in the order number.

Lengths (d) | ||

|---|---|---|

8D1xx2 | 8D1xx3 | |

8D1A2 | Yes | Yes |

8D1B2 | Yes | Yes |

8D1C2 | Yes | Yes |

Motor encoder system / Electronics option (e)

Motor encoder system / Electronics option (e)

8D1 | b | c | d | . | e | f | g | h | i | j | k | ll | - | m |

ACOPOSmotor Compact modules are equipped with EnDat 2.2 encoders and optionally available with 2 external connections. The external connections are a combination of a 24 VDC output and trigger input.

The respective variant of the module is specified in the form of a one-digit code (e) as part of the order number.

Order code (e) | Motor encoder system | Electronics option |

|---|---|---|

Encoder type | 2 external connections | |

A | B8 | --- |

B | B9 | --- |

G | B8 | Yes |

H | B9 | Yes |

EnDat 2.2 encoder

General information

Digital drive systems and position control loops require fast and highly secure transfer of data obtained from position measuring instruments. In addition, other data such as drive-specific characteristic values, correction tables, etc. should also be available. To ensure a high level of system security, measuring instruments must be integrated in routines for detecting errors and be able to perform diagnostics.

The EnDat interface from HEIDENHAIN is a digital, bidirectional interface for measuring instruments. It is able to output position values from incremental and absolute measuring instruments and can also read and update information on the measuring instrument or store new data there. Because it relies on serial data transfer, only 4 signal lines are needed. The data is transferred synchronous to the clock signal defined by the subsequent electronics. The transfer method (position values, parameters, diagnostics, etc.) is selected with mode commands that the subsequent electronics transmit to the measuring instrument.

Technical data

Encoder type / Order code (ee) | ||

|---|---|---|

B8 | B9 | |

Operating principle | Inductive | |

EnDat protocol | EnDat 2.2 | |

Single-turn/Multi-turn | S | M |

Revolutions | 1 | 4096 |

Resolution [bits single-turn / bits multi-turn] | 19/0 | 19/12 |

Accuracy [''] | 120 | |

Cutoff frequency ≥ [kHz] | Digital pos. in the encoder | |

Stator - Vibration during operation Max. [m/s2] | 400 | |

Rotor - Vibration during operation Max. [m/s2] | 600 | |

Max. shock during operation [m/s2] | 2000 | |

Probability of dangerous failure per hour (PFH) SIL 2 | ≤15 * 10-9 | |

Manufacturer's product ID | ECI 1119 FS EnDat22 | EQI 1131 FS EnDat22 |

Nominal speed (f)

Nominal speed (f)

8D1 | b | c | d | . | e | f | g | h | i | j | k | ll | - | m |

The nominal speed is specified as part of the order number in the form of a code (f).

Order code (f) | ||||

|---|---|---|---|---|

B | D | H | I | |

Nominal speed nN [rpm] | 1200 | 2000 | 4100 | 4500 |

Availability

Nominal speeds nN [rpm] | ||||

|---|---|---|---|---|

1200 | 2000 | 4100 | 4500 | |

8D1x22 | --- | --- | --- | Yes |

8D1x23 | --- | Yes | Yes | --- |

8D1x33 | Yes | --- | --- | --- |

Motor options (g)

Motor options (g)

8D1 | b | c | d | . | e | f | g | h | i | j | k | ll | - | m |

The motor option is specified as part of the order number in the form of a one-digit code (g).

8D1A

Order code (g) | Motor options | ||

|---|---|---|---|

Holding brake | Shaft end | Oil seal | |

0 | No | Smooth shaft | No |

1 | Keyed shaft | ||

2 | Yes | Smooth shaft | |

3 | Keyed shaft | ||

4 | No | Smooth shaft | Yes |

5 | Keyed shaft | ||

6 | Yes | Smooth shaft | |

7 | Keyed shaft | ||

8D1B / 8D1C

Order code (g) | Motor options | ||

|---|---|---|---|

Holding brake | Gearbox shaft end | Oil seal | |

0 | No | Gearbox options (k) | No |

2 | Yes | ||

Holding brake

The holding brake is a permanent magnet brake. Voltage (see the technical data) must be applied to release the brake. Based on principle, this type of holding brake exhibits a minimal amount of backlash.

The brake is designed as a holding brake. It not permitted to be used for operational braking! Loaded braking during an emergency stop is permitted but reduces its service life.

The required brake holding torque is determined based on the actual load torque. It is recommended by the brake manufacturer to take into account a safety factor of 2.

The holding brake is not intended for normal braking. The maximum motor torque far exceeds the holding torque for the brake.

The number of revolutions of the motor shaft with the holding brake applied is not permitted to exceed the value 3200 since safety function STO can no longer be ensured in this case. The current value of the revolutions when the holding brake is applied can be read out under parameter ID BRAKE_WEARMON_REVO.Values are only valid for size 2.

Technical data

Motor size | ||

|---|---|---|

8D1x2 | 8D1x3 | |

Holding torque MBr [Nm] | 2.2 | 3.2 |

Connected load POn [W] | 8.4 | 13.4 |

Maximum speed nmax [rpm] | 12000 | 12000 |

Supply current IOn [A] | 0.35 | 0.56 |

Supply voltage UOn [V] | 24 VDC +6% / -10% | 24 VDC +6% / -10% |

Moment of inertia JBr [kgcm²] | 0.07 | 0.38 |

Weight mBr [kg] | 0.16 | 0.29 |

Service life | Approx. 5,000,000 switching cycles 1) | Approx. 5,000,000 switching cycles 1) |

| 1) | This specification is only valid if all conditions are observed. Releasing and re-engaging corresponds to 1 switching cycle. The brake is designed as a holding brake. It not permitted to be used for operational braking! Loaded braking during an emergency stop is permitted but reduces its service life. |

8D1A - Shaft end design

ACOPOSmotor Compact modules (8D1A) can be delivered with a smooth shaft end or keyed shaft end.

A smooth shaft end is used for a force-fit shaft-hub connection and guarantees a backlash-free connection between the shaft and hub as well as a high degree of operating smoothness. The end of the shaft has a threaded center hole.

A keyed shaft end is used for a form-fit torque transfer with low demands on the shaft-hub connection and for handling torque in a constant direction.

The keyways for ACOPOSmotor Compact modules conform to keyway form N1 per DIN 6885-1. Form A keyed shafts that conform to DIN 6885-1 are used. Balancing motors with keyways is done using the shaft and fitment key convention per DIN ISO 8821.

The end of the shaft has a threaded center hole that can be used to install machine actuators with shaft end cover plates.

8D1A - Oil seal

All ACOPOSmotor Compact modules without gearbox (8D1A) are available with an optional form A oil seal per DIN 3760.

With an oil seal, the ACOPOSmotor Compact modules meet the requirements for IP65 protection per EN 60529.

Proper lubrication of the oil seal must be ensured throughout the entire service life of the motor.

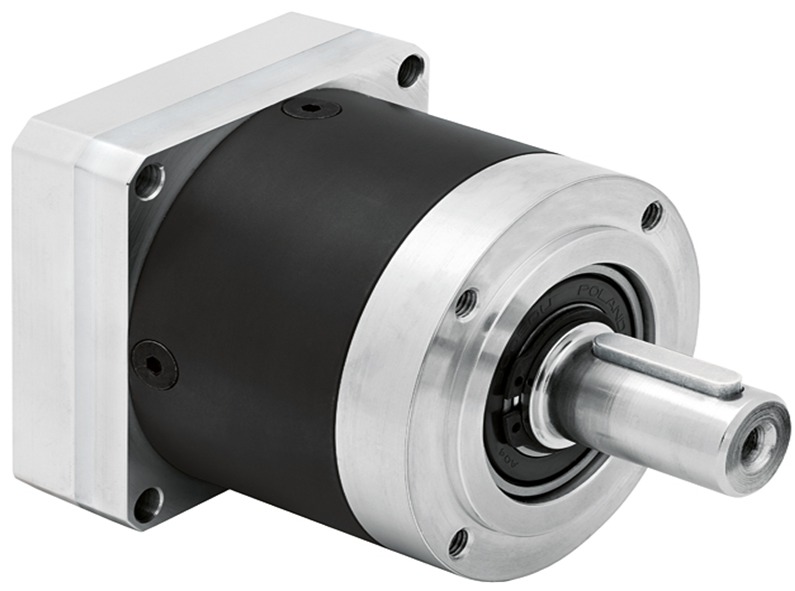

Gearbox (h)

Gearbox (h)

8D1 | b | c | d | . | e | f | g | h | i | j | k | ll | - | m |

The gearbox is specified by a code (k) in the order key. Code 0 must be used in the order code for no gearbox.

8D1A

Order code | Gearbox type | Class | Toothing type | Degree of protection | Gearbox type - Description | |

|---|---|---|---|---|---|---|

0 | Without gearbox | --- | --- | --- |  | --- |

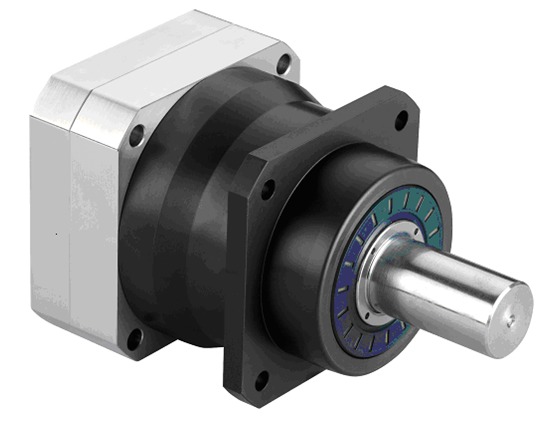

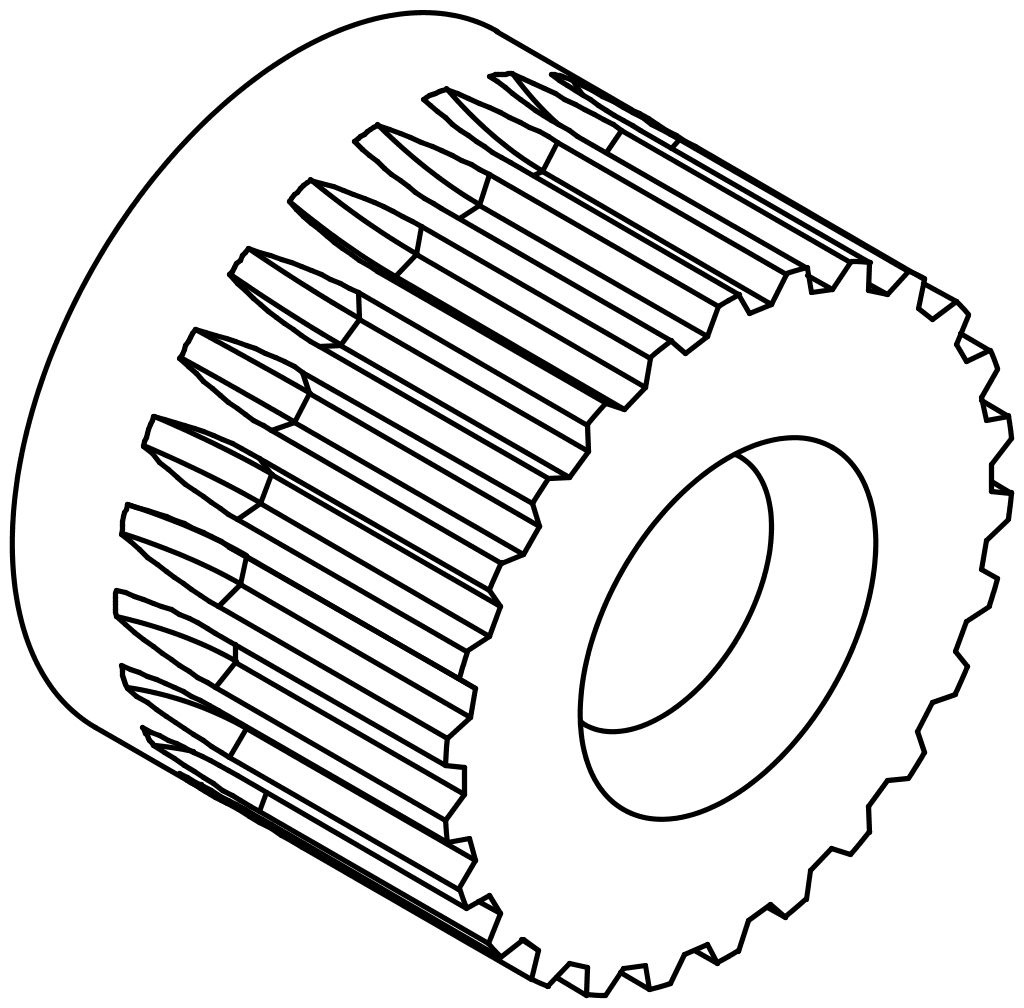

8D1B

Order code | Gearbox type | Class | Toothing type | Degree of protection 1) | Gearbox type - Description | |

|---|---|---|---|---|---|---|

B | 8GM40 | Standard | Straight | IP54 |  | Planetary gearbox with output shaft |

C | 8GM45 |  | ||||

D | 8GM50 |  | ||||

E | 8GM55 | IP65 |  | |||

H | 8GG40 | IP54 |  | Planetary gearbox with output flange | ||

| 1) | Degree of protection valid for the entire 8D1B module |

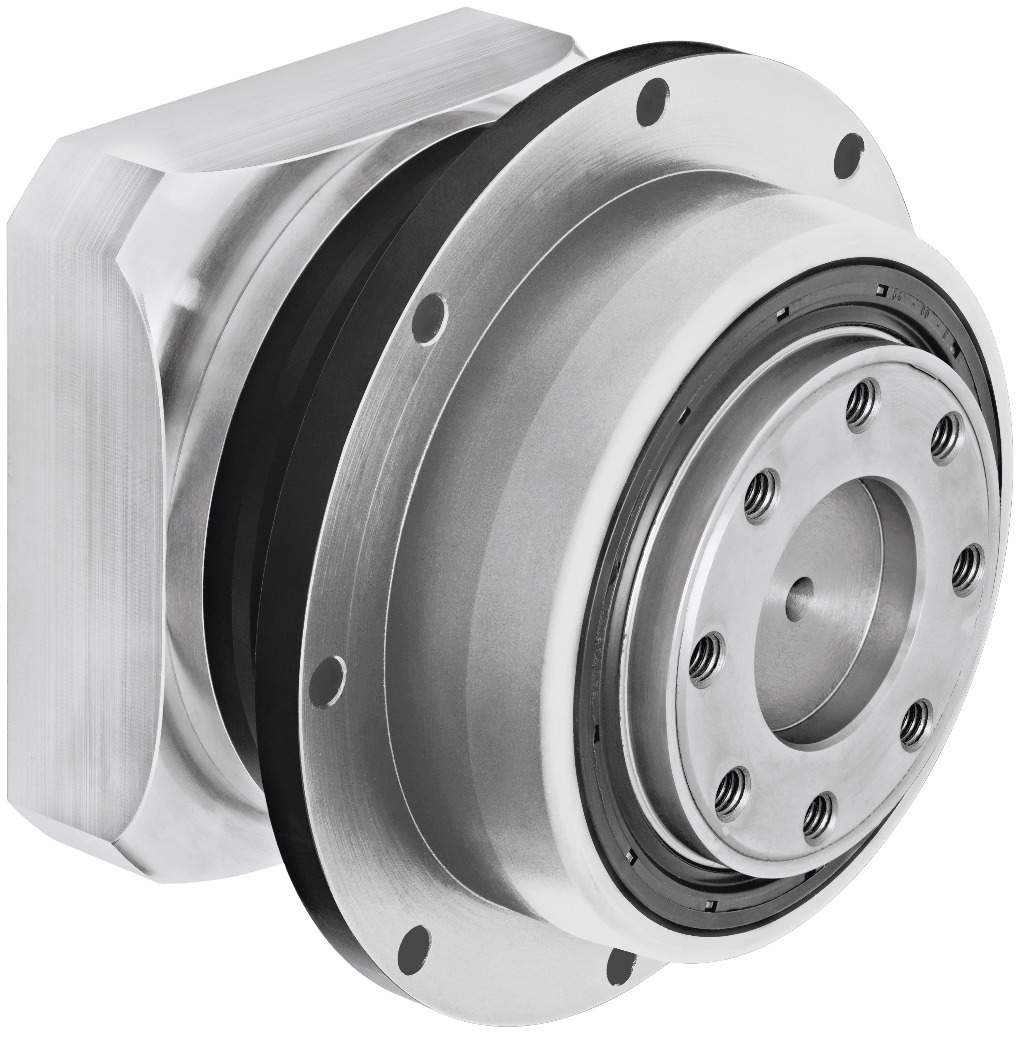

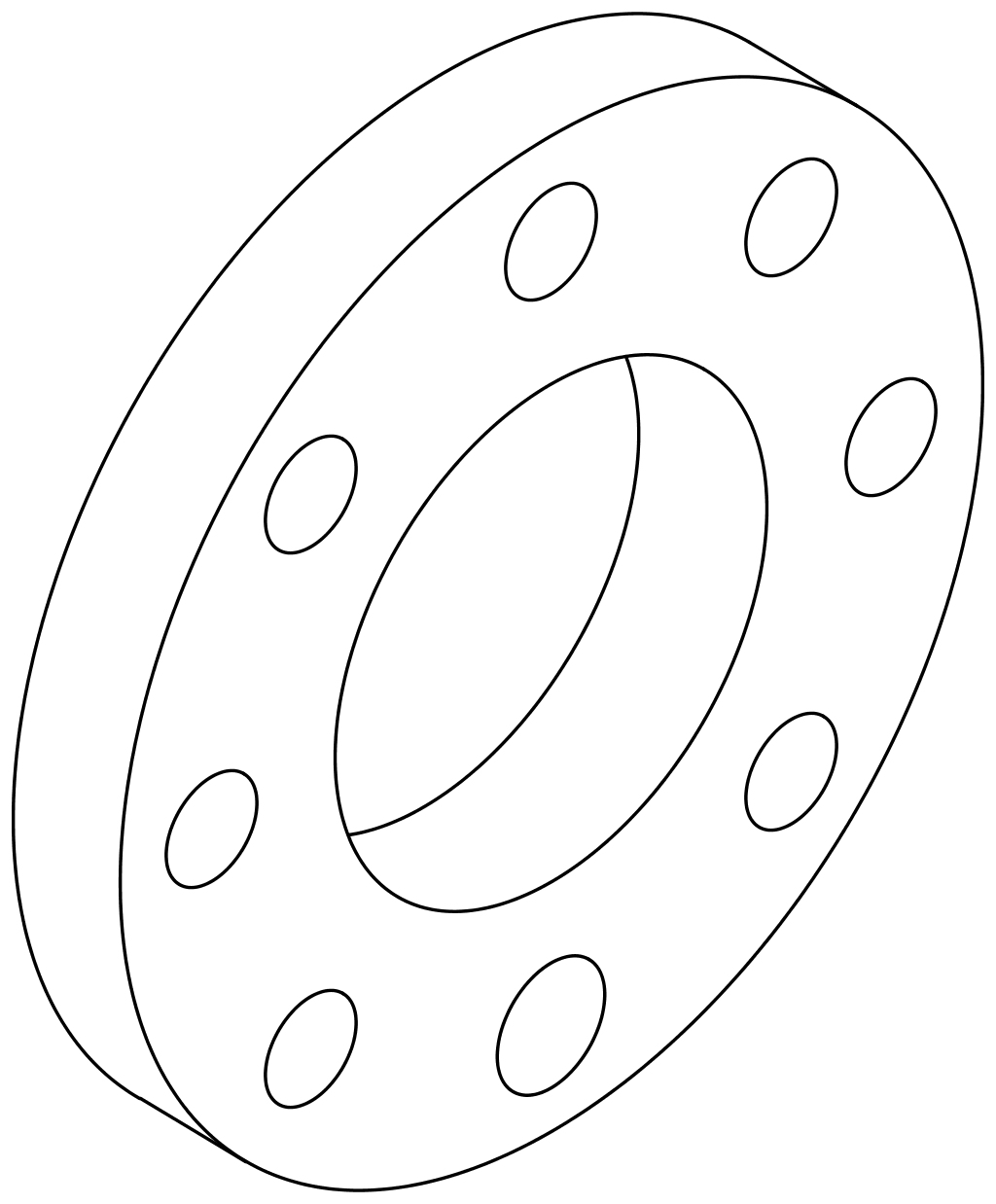

8D1C

Order code | Gearbox type | Class | Toothing type | Degree of protection 2) | Gearbox type - Description | |

|---|---|---|---|---|---|---|

B | 8GP40 | Standard | Straight | IP54 |  | Planetary gearbox with output shaft |

C | 8GP45 |  | ||||

D | 8GP50 |  | ||||

E | 8GP55 |  | ||||

F | 8GP60 | Premium 1) |  | |||

G | 8GP70 | Helical |  | |||

H | 8GF40 | Standard | Straight |  | Planetary gearbox with output flange | |

I | 8GF60 | Premium 1) | Straight |  | ||

J | 8GF70 | Helical |  | |||

K | 8GA40 | Standard | Straight |  | Angular planetary gearbox | |

L | 8GA45 |  | ||||

M | 8GA50 |  | ||||

N | 8GA55 |  | ||||

P | 8GA60 | Premium | Spiral bevel |  | ||

| 1) | Premium class For applications that demand high precision. In addition to standard spur toothing, helical gearing, which runs even smoother and quieter, is also possible. |

| 2) | Degree of protection valid for the entire 8D1C module |

Gearbox size (i)

Gearbox size (i)

8D1 | b | c | d | . | e | f | g | h | i | j | k | ll | - | m |

B&R gearboxes are available in different sizes.

The gearbox size is specified by a code (i) in the order key (e.g. H).

The larger the size (e.g. 080), the larger the flange dimensions and power data of the respective gearbox.

8D1A | 8D1B | 8D1C |

|---|---|---|

Order code ... Without gearbox | Order code ... Gearbox size | Order code ... Gearbox size |

0 ... Without gearbox | D ... 060 | D ... 060 |

8D1B (8GM / 8GG) - Possible gearbox sizes

Gearbox series | Gearbox size1) |

|---|---|

8GM40 | 060 |

8GM40 | 080 |

8GM45 | 067 |

8GM45 | 089 |

8GM50 | 070 |

8GM50 | 090 |

8GM55 | 060 |

8GM55 | 080 |

8GG40 | 064 |

8GG40 | 090 |

8D1C (8GP) - Possible gearbox sizes

Gearbox series | Gearbox size2) |

|---|---|

8GP40 | 060, 080 |

8GP45 | 067, 089 |

8GP50 | 070, 090 |

8GP55 | 060, 080 |

8GP60 | 070, 090 |

8GP70 | 070, 090 |

8D1C (8GF) - Possible gearbox sizes

Gearbox series | Gearbox size2) |

|---|---|

8GF40 | 064 |

8GF60 | 064, 090 |

8GF70 | 064, 090 |

8D1C (8GA) - Possible gearbox sizes

Gearbox series | Gearbox size2) |

|---|---|

8GA40 | 060, 080 |

8GA45 | 067, 089 |

8GA50 | 070, 090 |

8GA55 | 064, 090 |

8GA60 | 070, 090 |

| 1) | 1-stage or 2-stage: Defined only by the selected gear ratio. |

| 2) | 1-stage, 2-stage or 3-stage: Defined only by the selected gear ratio. |

Gear ratio (j)

Gear ratio (j)

8D1 | b | c | d | . | e | f | g | h | i | j | k | ll | - | m |

B&R gearboxes are available with different gear ratios.

The code (j) in the order number contains the gear ratio.

8D1A | 8D1B / 8D1C | ||

|---|---|---|---|

Order code ... Without gearbox | Order code ... Gear ratio | ||

0 ... Without gearbox | B ... 003 | I ... 012 | Q ... 040 |

8D1B - Possible gear ratios

Gearbox series / Gearbox size | Gear ratio | ||

|---|---|---|---|

1-stage: | 2-stage: | 3-stage: | |

8GM40 / 060 / 080 | 005, 008, 010 | 015, 020, 025, 032, 040, 064, 100 | --- |

8GM45 / 067 / 089 | 005, 008, 010 | 015, 020, 025, 032, 040, 064, 100 | --- |

8GM50 / 070 / 090 | 005, 008, 010 | 015, 020, 025, 032, 040, 064, 100 | --- |

8GM55 / 060 / 080 | 005, 008, 010 | 015, 020, 025, 032, 040, 064, 100 | --- |

8GG40 / 064 / 090 | 005, 008, 010 | 015, 020, 025, 032, 040, 064, 100 | --- |

8D1C (8GP) - Possible gear ratios

Gearbox series / Gearbox size | Gear ratio | ||

|---|---|---|---|

1-stage: | 2-stage: | 3-stage: | |

8GP40 / 060 | 003, 004, 007 | 009, 012, 016 | --- |

8GP40 / 080 | 003, 004, 005, 007, 008, 010 | 009, 012, 015, 016, 020, 025, 032, 040, 064, 100 | 060, 080 |

8GP45 / 067 | 003, 004, 007 | 009, 012, 016 | --- |

8GP45 / 089 | 003, 004, 005, 007, 008, 010 | 009, 012, 015, 016, 020, 025, 032, 040, 064, 100 | 060, 080 |

8GP50 / 070 | 003, 004, 007 | 009, 012, 016 | --- |

8GP50 / 090 | 003, 004, 005, 007, 008, 010 | 009, 012, 015, 016, 020, 025, 032, 040, 064, 100 | --- |

8GP55 / 060 | 003, 004, 007 | 009, 012, 016 | --- |

8GP55 / 080 | 003, 004, 005, 007, 008, 010 | 009, 012, 015, 016, 020, 025, 032, 040, 064, 100 | --- |

8GP60 / 070 | 003, 004, 005, 007, 008, 010 | 012, 015, 016, 020, 025, 032, 040, 064, 100 | --- |

8GP60 / 090 | 003, 004, 005, 007, 008, 010 | 012, 015, 016, 020, 025, 032, 040, 064, 100 | |

8GP70 / 070 | 003, 004, 005, 007, 010 | 012, 015, 016, 020, 025, 035, 040, 050, 070, 100 | --- |

8GP70 / 090 | 003, 004, 005, 007, 010 | 012, 015, 016, 020, 025, 035, 040, 050, 070, 100 | |

8D1C (8GF) - Possible gear ratios

Gearbox series / Gearbox size | Gear ratio | ||

|---|---|---|---|

1-stage: | 2-stage: | 3-stage: | |

8GF40 / 064 | 003, 004, 007 | 009, 012, 016 | --- |

8GF60 / 064 | 004, 005, 007, 008, 010 | 016, 020, 025, 032, 040, 050, 064, 100 | --- |

8GF60 / 090 | 004, 005, 007, 008, 010 | 016, 020, 025, 032, 040, 050, 064, 100 | |

8GF70 / 064 | 004, 005, 007, 010 | 016, 020, 025, 035, 040, 050, 070, 100 | --- |

8GF70 / 090 | 004, 005, 007, 010 | 016, 020, 025, 035, 040, 050, 070, 100 | |

8D1C (8GA) - Possible gear ratios

Gearbox series / Gearbox size | Gear ratio | ||

|---|---|---|---|

1-stage: | 2-stage: | 3-stage: | |

8GA40 / 060 | 003, 004, 005, 007, 008, 010 | 009, 012, 015, 016, 020, 025, 032, 040, 064, 100 | 060, 080 |

8GA40 / 080 | 003, 004, 005, 007, 008, 010 | 009, 012, 015, 016, 020, 025, 032, 040, 064, 100 | 060, 080 |

8GA45 / 067 | 003, 004, 005, 007, 008, 010 | 009, 012, 015, 016, 020, 025, 032, 040, 064, 100 | 060, 080 |

8GA45 / 089 | 003, 004, 005, 007, 008, 010 | 009, 012, 015, 016, 020, 025, 032, 040, 064, 100 | 060, 080 |

8GA50 / 070 | 003, 004, 005, 007, 008, 010 | 009, 012, 015, 016, 020, 025, 032, 040, 064, 100 | --- |

8GA50 / 090 | 003, 004, 005, 007, 008, 010 | 009, 012, 015, 016, 020, 025, 032, 040, 064, 100 | |

8GA55 / 064 | 003, 004, 005, 007, 008, 010 | 009, 012, 015, 016, 020, 025, 032, 040, 064, 100 | --- |

8GA55 / 090 | 003, 004, 005, 007, 008, 010 | 009, 012, 015, 016, 020, 025, 032, 040, 064, 100 | |

8GA60 / 070 | 004, 005, 008, 010 | 016, 020, 025, 032, 040, 050, 064, 100 | --- |

8GA60 / 090 | 004, 005, 008, 010 | 016, 020, 025, 032, 040, 050, 064, 100 | |

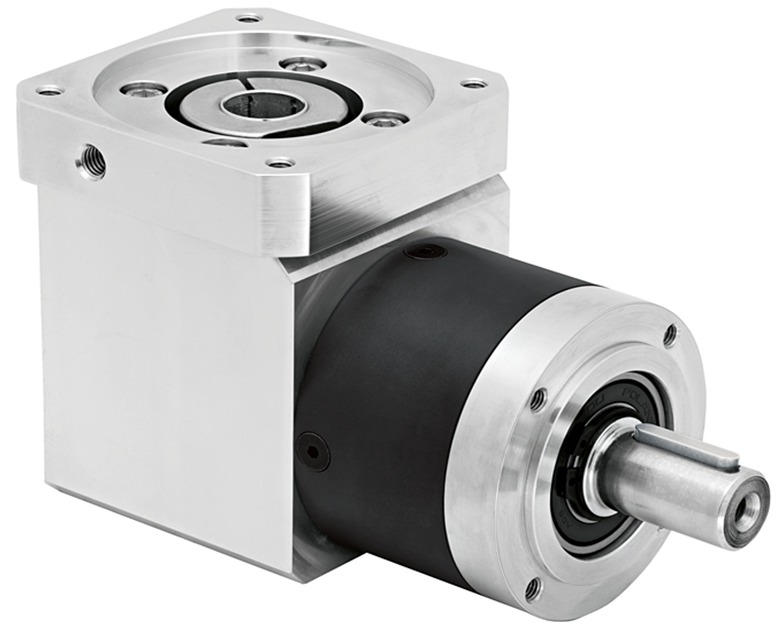

Gearbox options (k)

Gearbox options (k)

8D1 | b | c | d | . | e | f | g | h | i | j | k | ll | - | m |

B&R gearboxes are available with various options.

The respective option is specified by a character (k) in the order key.

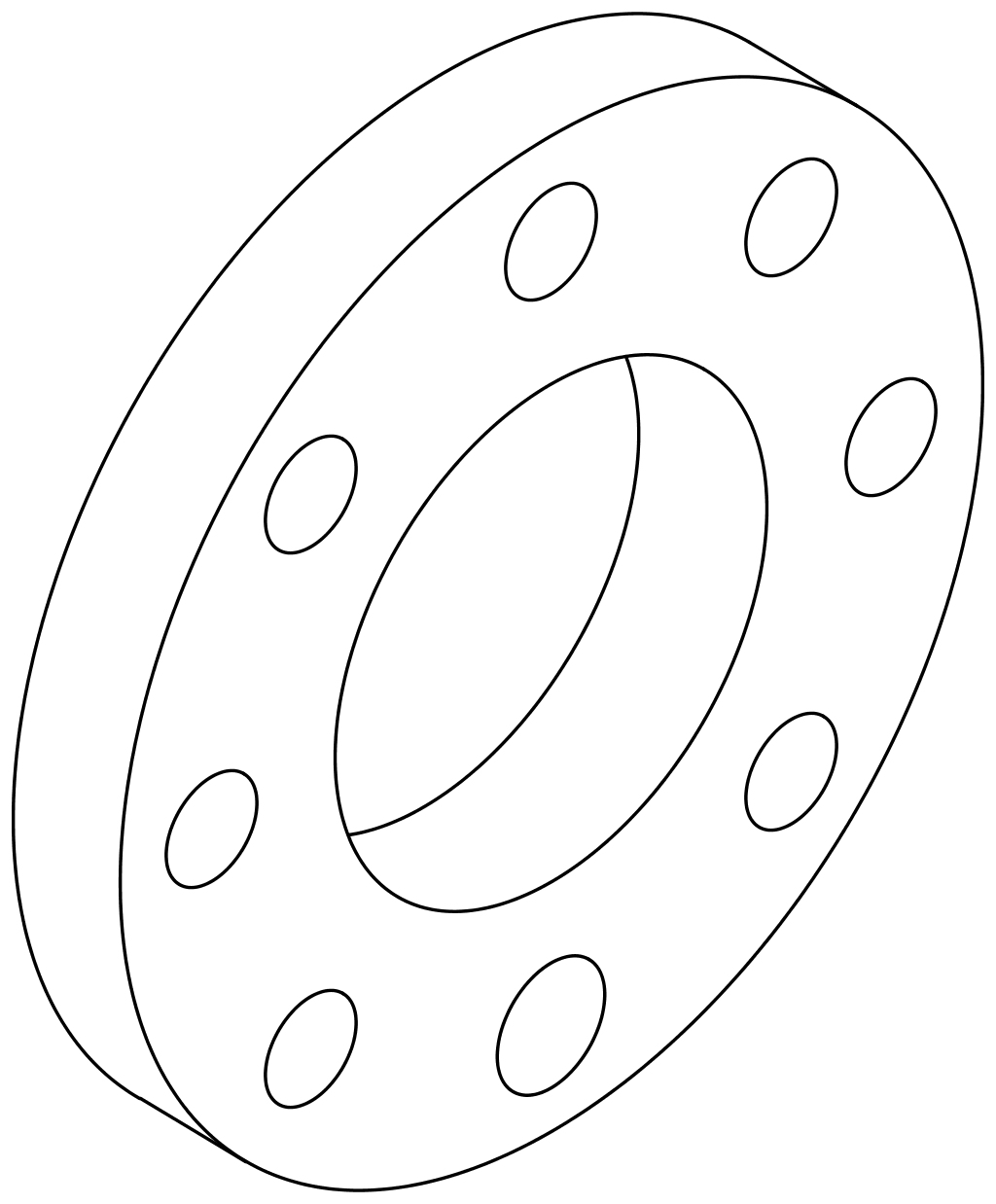

Order code | Output shaft | Variant | Backlash 1) | |

|---|---|---|---|---|

0 |  | Without gearbox (8D1A) | --- | --- |

A |  | Flange output shaft | Standard | Standard |

B | Reduced backlash 1) | |||

C | Food-safe lubrication | Standard | ||

D | Reduced backlash 1) | |||

E |  | Smooth shaft | Standard | Standard |

F | Reduced backlash 1) | |||

G | Food-safe lubrication | Standard | ||

H | Reduced backlash 1) | |||

I |  | Keyed shaft DIN 6885 T1 | Standard | Standard |

J | Reduced backlash 1) | |||

K | Food-safe lubrication | Standard | ||

L | Reduced backlash 1) | |||

M |  | Toothed shaft DIN 5480 | Standard | Standard |

N | Reduced backlash 1) | |||

P | Food-safe lubrication | Standard | ||

Q | Reduced backlash 1) | |||

R |  | Flange output shaft with dowel pin hole | Standard | Standard |

S | Reduced backlash 1) | |||

T | Food-safe lubrication | Standard | ||

U | Reduced backlash 1) | |||

| 1) | Reduced backlash is only available for premium gearboxes: 8GP60, 8GP70 / 8GA60, 8GA75 / 8GF60, 8GF70. |

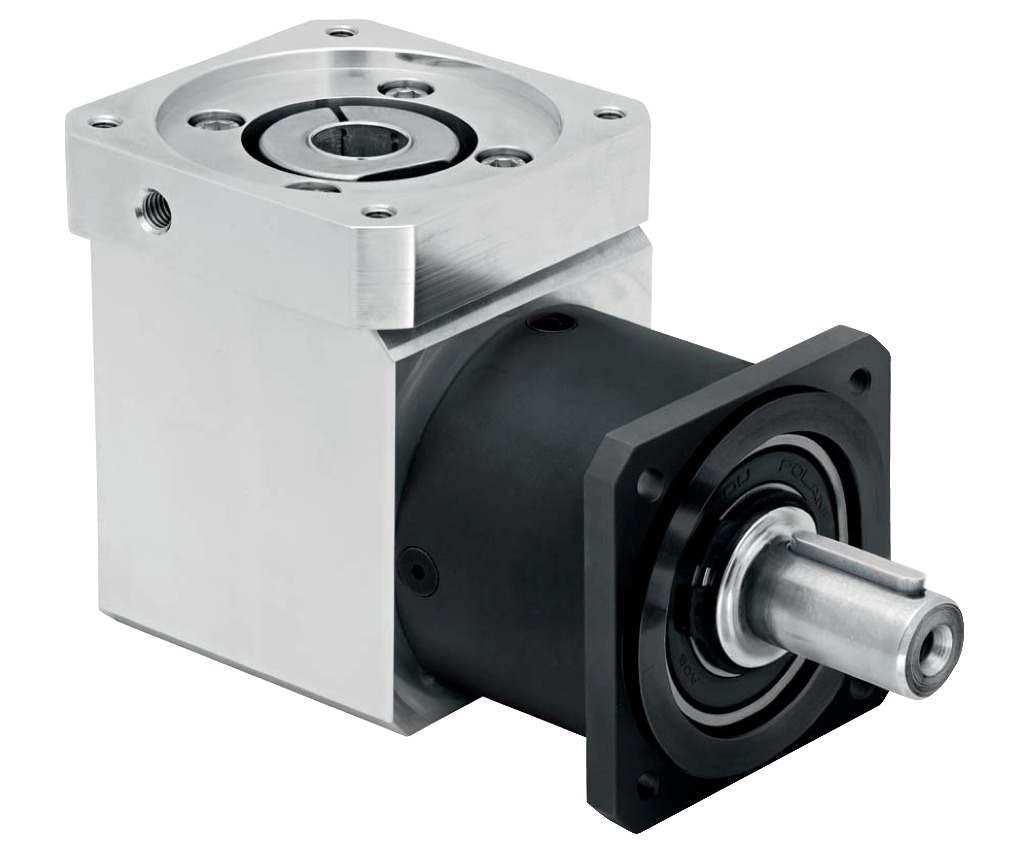

Special motor options (ll)

Special motor options (ll)

8D1 | b | c | d | . | e | f | g | h | i | j | k | ll | - | m |

The special motor options are specified as part of the order number in the form of a 2-digit code (ll).

For ACOPOSmotor Compact 8D1C modules with an 8GA angular gearbox, a mounting position for the gearbox must be defined using code (II).

For all other motors, there are no special motor options and code 00 must be used.

Valid values: 00, 0A, 0B, 0C, 0D

Order code (ll) | ||||||

|---|---|---|---|---|---|---|

Without gearbox | With 8GP / 8GF gearbox | With 8GA angular gearbox (mounting position) | ||||

(A) | (B) | (C) | (D) | |||

8D1A | 00 | --- | --- | --- | --- | --- |

8D1B | --- | 00 | --- | --- | --- | --- |

8D1C | --- | 00 | 0A  | 0B  | 0C  | 0D  |

8D1C example:

ACOPOSmotor Compact 8D1C with 8GA angular gearbox in mounting position A (code 0A)

Order key =8D1Cxx.xxxxx0A-1

Motor version (h)

Motor version (h)

8D1 | b | c | d | . | e | f | g | h | i | j | k | ll | - | m |

The motor version is specified as a code (h) in the order number. Motor version 1 is currently valid.