Additional information

8LTA / 8LTB / 8LTQ / 8LTJ / 8LTK / 8LTS

General information | 8LTA / 8LTB / 8LTQ | 8LTJ / 8LTK / 8LTS |

|---|---|---|

CE certification | Yes | |

C-UR-US listed | Yes | |

UL file number | E235396 | |

Electrical properties | 8LTA / 8LTB / 8LTQ | 8LTJ / 8LTK / 8LTS |

|---|---|---|

Mains input voltage on the servo drive | 3x 400 VAC ... 3x 480 VAC ±10% | |

Connection type: | speedtec circular connector from Intercontec | |

Efficiency | Typ. >90% | |

Thermal properties | 8LTA / 8LTB / 8LTQ | 8LTJ / 8LTK / 8LTS |

|---|---|---|

Insulation class per EN 60034-1 | F | |

Methods of cooling per EN 60034-6 (IC code) | Self-cooling Free circulation surface cooling (IC4A0A0) | External cooling Surface cooling with built-in heat exchanger (IC7A0W7, IC7A0U7) |

Thermal motor protection per EN 60034-11 | Maximum winding temperature 145°C (limited to 110°C by the thermal motor protection in the ACOPOS servo drive or the ACOPOSmulti drive system) | |

Mechanical properties | 8LTA / 8LTB / 8LTQ | 8LTJ / 8LTK / 8LTS |

|---|---|---|

Vibration severity per EN 60034-14 | Vibration severity level RValid for all motors with an axis height greater than 56 mm. | |

Bearing service life calculation | Based on DIN ISO 281 | |

Eye bolt per DIN 580 | Yes | |

Oil seal per DIN 3760 | Form A | |

Mounting flange per DIN 42948 | Form A | |

Radial runout, concentricity and axial runout of mounting flange per DIN 42955 | Tolerance R | |

Coating Description Color | Water-based coating 98160 *IDROLIN/E SM SEMIOPACO NERO RAL 9005-C.452 RAL 9005 flat; shaft end and flange front metallic glossy | |

Operating conditions | 8LTA / 8LTB / 8LTQ | 8LTJ / 8LTK / 8LTS |

|---|---|---|

Rating class, operating mode per EN 60034-1 | S1 - Continuous operation | |

Ambient temperature during operation | -15 to 40°C | |

Relative humidity during operation | 5 to 95%, non-condensing | |

Reduction of nominal and stall current as well as nominal and stall torque at temperatures above 40°C | 5% per 5°C | |

Max. ambient temperature during operation | 55°CContinuous operation of torque motors from an ambient temperature 40°C to max. 55°C is possible, but this results in premature aging. | |

Reduction of nominal and stall current as well as nominal and stall torque at installation elevations starting at 1,000 m above sea level | 5% per 1,000 m | |

Maximum installation elevation | 1,000 mRequirements that go beyond this must be arranged with B&R. | |

Max. flange temperature | 65°C | |

Degree of protection per EN 60034-5 (IP code): Degree of protection with optional oil seal (DIN 3760): | IP54 IP65 | |

Type of construction and mounting arrangement per EN 60034-7 (IM code) | Horizontal (IM3001) Vertical, motor suspended from the machine (IM 3011)With the IM 3011 type of construction and mounting arrangement (vertical, motor suspended from the machine), there is a risk of production fluids or oils penetrating the motor on the flange side. Motors or motor-gearbox combinations that should be used with this mounting arrangement must therefore have at least IP65 protection on the flange side. Vertical, motor stands on the machine (IM3031) | Horizontal (IM 3001)Permissible water connection direction: Water inlet on top Vertical, motor suspended from the machine (IM 3011)With the IM 3011 type of construction and mounting arrangement (vertical, motor suspended from the machine), there is a risk of production fluids or oils penetrating the motor on the flange side. Motors or motor-gearbox combinations that should be used with this mounting arrangement must therefore have at least IP65 protection on the flange side.Permissible water connection direction: Water inlet on bottom Vertical, motor standing on the machine (IM 3031)Permissible water connection direction: Water inlet on bottom |

Liquid cooling | 8LTJ94 | 8LTJ95 | 8LTJ96 | 8LTJ97 |

|---|---|---|---|---|

Coolant | WaterWater must be clean and demineralized. For corrosion and germ protection, sufficient additives must be added according to the recommendation of the additive manufacturer. Information as to whether these additives result in reduced heat capacity of the coolant must be requested from the additive manufacturer and taken into account during motor operation. | |||

Materials in the motor that come into contact with coolant | Stainless steel, brass (connections) | |||

Coolant pH value (at 20°C) | 6 - 7.5 | |||

Total hardness of coolant | 1.4 - 2.4 mmol/l | |||

Max. size of foreign bodies in coolant | <0.1 mm | |||

Chloride content of coolant | <120 mg/l (ppm) | |||

Sulphate content of coolant | <200 mg/l (ppm) | |||

Oil content of coolant | <1 mg/l (ppm) | |||

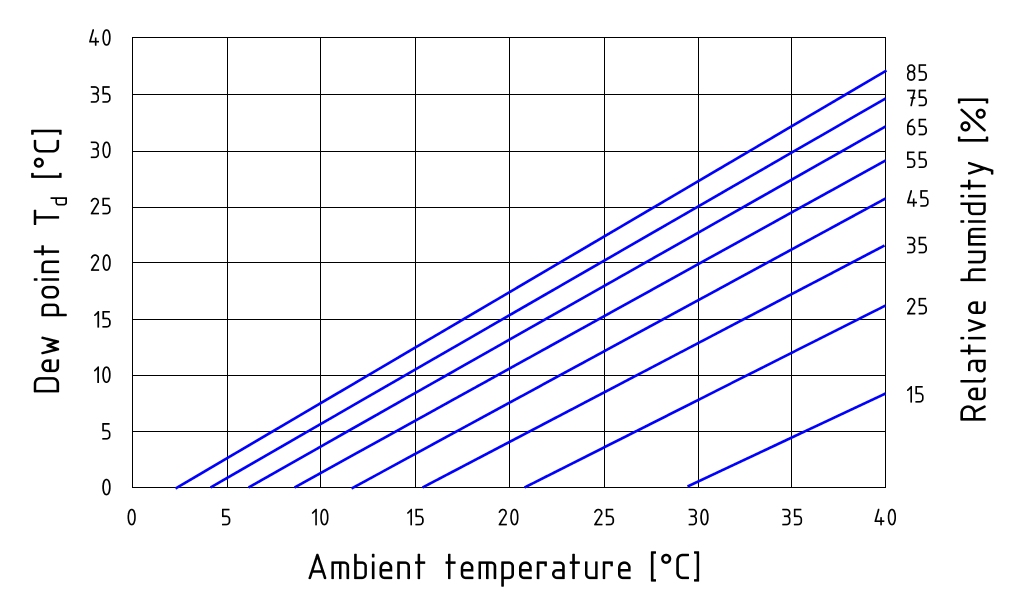

Coolant inlet temperature | 5 to 25°C | |||

Max. coolant inlet temperature | 30°C | |||

Dew pointDiagram: The "dew point" (left) results from the intersection of "ambient temperature" (below) and "relative humidity" (right). |  | |||

Increase of nominal and stall current as well as nominal and stall torque for water cooling | 70% | |||

Nominal flow rate | 5 l/minThe pressure drop depends on the volumetric flow rate. | |||

Pressure drop | 0.060 bar | 0.065 bar | 0.065 bar | 0.070 bar |

Coolant inlet pressure | 3.85 bar | 3.80 bar | 3.75 bar | 3.70 bar |

Max. coolant inlet pressure | 10 barThe max. coolant inlet pressure is the maximum permissible pressure in the water-cooled motor housing. | |||

Coolant line connection | 2 x 1/4"G (internal threads) | |||

Storage and transport conditions | 8LTA / 8LTB / 8LTQ | 8LTJ / 8LTK / 8LTS |

|---|---|---|

Storage temperature | -20 to 60°C | |

Relative humidity during storage | Max. 90%, non-condensing | |

Transport temperature | -20 to 60°C | |

Relative humidity during transport | Max. 90%, non-condensing | |