8LS | b | c | d | . | ee | nnn | ff | gg | - | h | ||||||||||||||||

Cooling / Construction type | ||||||||||||||||||||||||||

Size | ||||||||||||||||||||||||||

Length | ||||||||||||||||||||||||||

Motor encoder system | ||||||||||||||||||||||||||

Nominal speed | ||||||||||||||||||||||||||

Motor options | ||||||||||||||||||||||||||

Special motor options | ||||||||||||||||||||||||||

Motor version | ||||||||||||||||||||||||||

Order keys only provide information about possible combinations in exceptional cases.

Information about possible combinations is available in the CAD configurator.

Additional information

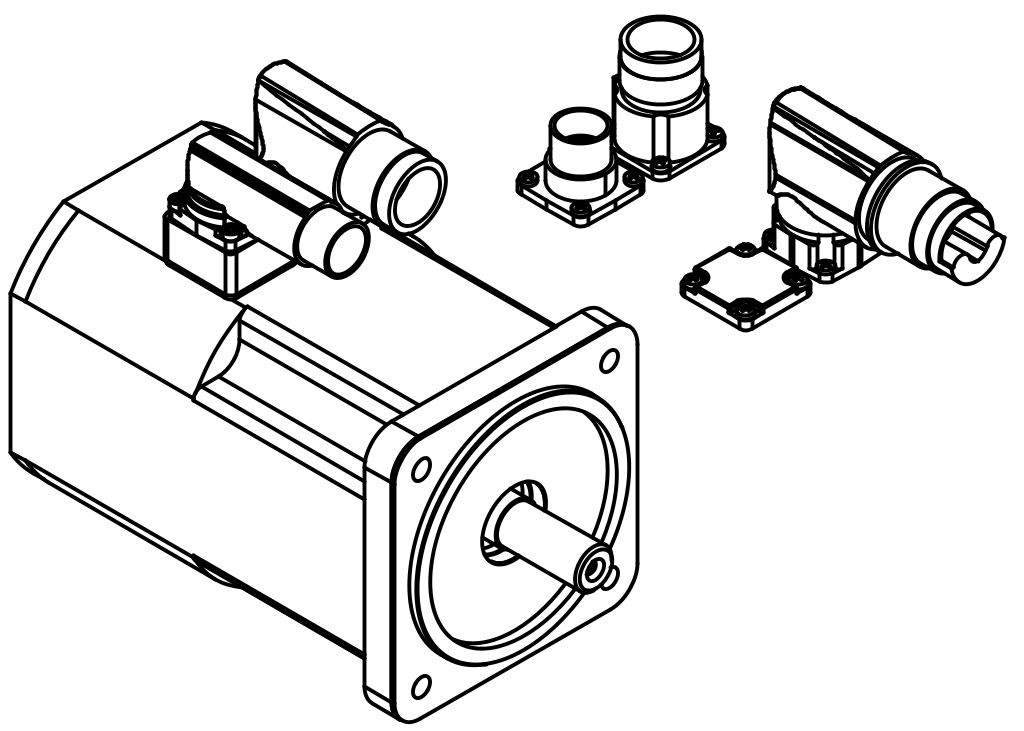

8LSN synchronous motors

8LSN - General motor data

8LSN - Order key

Cooling type / Construction type (b)

Cooling type / Construction type (b)

8LS | b | c | d | . | ee | nnn | ff | gg | - | h | |||||||||||

The cooling type is defined by a character (b) in the order number.

Cooling type (b) | Connection technology (see motor options) | Available mounting types | ||

|---|---|---|---|---|

Mounting flange | Mounting flange and mounting base | |||

8LSN | Self-cooling, increased mass moment of inertia | Straight built-in connector | Yes | --- |

Angled built-in connector (swivel) | ||||

Single-cable solution (hybrid) | ||||

8LSN

| Cooling type 8LSN is self-cooling and has a slim, elongated design. These motors must be attached to the machine with the mounting flange, which also serves as a cooling surface. |

Size (c)

Size (c)

8LS | b | c | d | . | ee | nnn | ff | gg | - | h | |||||||||||

| 8LSN three-phase synchronous motors are available in sizes 4 and 5. These differ in dimensions (especially flange dimensions) and power data. The sizes are differentiated by a digit (c) in the order number. The larger the number, the larger the flange dimensions and power data of the respective motor. |

Availability

Available sizes (c) | ||

|---|---|---|

4 | 5 | |

8LSN | Yes | YesWith sensitive applications, natural resonances can occur that can have a negative effect on the process. Special attention must be paid to natural resonances during commissioning. |

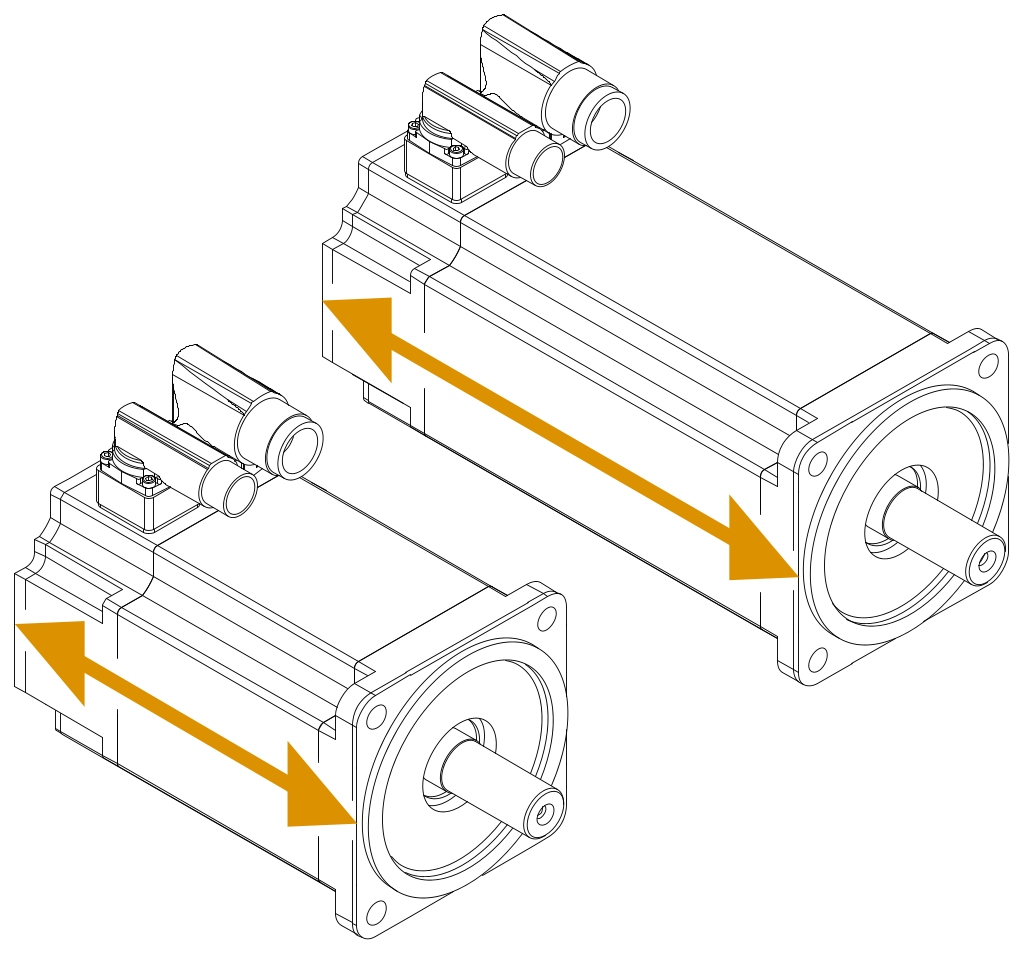

Length (d)

Length (d)

8LS | b | c | d | . | ee | nnn | ff | gg | - | h | |||||||||||

| 8LSN three-phase synchronous motors are available in different lengths. These differ in the power data with identical flange dimensions. The lengths are differentiated by a number (d) in the order number. The larger the number, the longer the respective motor. |

Availability

Available lengths (d) | ||||||

|---|---|---|---|---|---|---|

3 8LSN43 | 4 8LSN44 | 5 8LSN45 | 6 8LSN46 | 7 8LSN47 | 8 8LSN48 | |

8LSN4 | Yes | Yes | Yes | Yes | --- | --- |

Available lengths (d) | ||||||

|---|---|---|---|---|---|---|

3 8LSN53 | 4 8LSN54 | 5 8LSN55 | 6 8LSN56 | 7 8LSN57 | 8 8LSN58 | |

8LSN5 | --- | Yes | Yes | Yes | Yes | --- |

Motor encoder system (ee)

Motor encoder system (ee)

8LS | b | c | d | . | ee | nnn | ff | gg | - | h | |||||||||||

8LSN three-phase synchronous motors are available with EnDat encoders as well as resolvers. The motor encoder system is specified as part of the order number in the form of a 2-digit code (ee).

Resolver

Technical data | Order code (ee) |

|---|---|

R0 | |

Precision ['] | 10 |

Vibration during operation [m/s2] | 10 < f ≤ 500 Hz: ≤196 |

Shock during operation [m/s2] (11 ms duration) | ≤981 |

Availability | Available resolvers / Order code (ee) |

|---|---|

R0 | |

8LSN4...-0 | Yes |

8LSN5...-0 | Yes |

8LSN....-3 | --- |

Inductive EnDat encoders

Technical data | Encoder type / Order code (ee) | |||||

|---|---|---|---|---|---|---|

EA | EB | DA | DB | SA | SB | |

Operating principle | Inductive | |||||

EnDat protocol | 2.1 | 2.1 | 2.2 | 2.2 | 2.2 | 2.2 |

Functional safety1) | --- | --- | Yes | Yes | Yes | Yes |

Single-turn/Multi-turn | S | M | S | M | S | M |

Revolutions | 1 | 4096 | 1 | 4096 | 1 | 4096 |

Resolution [bits single-turn / bits multi-turn] | 19/0 | 19/12 | 19/0 | 19/12 | 19/0 | 19/12 |

Precision ["] | 180 | 65 | ||||

Cutoff frequency ≥ [kHz] | 6 | Digital pos. in the encoder | ||||

Stator - Vibration during operation Max. [m/s2] | 200 | 400 | ||||

Rotor - Vibration during operation Max. [m/s2] | 200 | 600 | ||||

Max. shock during operation [m/s2] | 2000 | 2000 | ||||

Probability of dangerous failure per hour (PFH) SIL 2 | --- | --- | ≤15 * 10-9 | |||

Manufacturer's product ID | ECI 1319 | EQI 1331 | ECI 1319 FS | EQI 1331 FS | ECI 1319 FS | EQI 1331 FS |

| 1) | See appendix B "Safety level overview for ACOPOS product family safety functions" in the SafeMOTION user's manual (MAACPMSAFEMC-ENG) in the Downloads section of the B&R website (www.br-automation.com). There are additional limitations when combining B&R motors with a gearbox, see section "1.2.1 ACOPOSmulti SafeMOTION EnDat 2.2 and ACOPOS P3 SafeMOTION" in the SafeMOTION user's manual (MAACPMSAFEMC-ENG) in the Downloads section of the B&R website (www.br-automation.com). |

Availability | Available encoders / Order code (ee) | |||||

|---|---|---|---|---|---|---|

EA | EB 2) | DA | DB | SA | SB | |

8LSN4...-0 | Yes | Yes | --- | --- | --- | --- |

8LSN4...-3 | --- | --- | Yes | Yes | Yes | Yes |

8LSN5...-0 | Yes | Yes | --- | --- | --- | --- |

8LSN5...-3 | --- | --- | Yes | Yes | Yes | Yes |

| 2) | Motor type EB requires at least the following versions (ACP10_SYS version or firmware version) of the ACOPOS operating systems: |

Optical EnDat encoders

Technical data | Encoder type / Order code (ee) | |||||

|---|---|---|---|---|---|---|

E0 | E1 | D0 | D1 | S0 | S1 | |

Operating principle | Optical | |||||

EnDat protocol | 2.1 | 2.1 | 2.2 | 2.2 | 2.2 | 2.2 |

Functional safety1) | --- | --- | Yes | Yes | Yes | Yes |

Single-turn/Multi-turn | S | M | S | M | S | M |

Revolutions | 1 | 4096 | 1 | 4096 | 1 | 4096 |

Resolution [bits single-turn / bits multi-turn] | 13/0 | 13/12 | 25/0 | 25/12 | 25/0 | 25/12 |

Precision ["] | 60 | 20 | ||||

Cutoff frequency ≥ [kHz] | 130 | Digital pos. in the encoder | ||||

Stator - Vibration during operation Max. [m/s2] | 300 | |||||

Rotor - Vibration during operation Max. [m/s2] | 300 | |||||

Max. shock during operation [m/s2] | 2000 | |||||

Probability of dangerous failure per hour (PFH) SIL 2 | --- | --- | ≤10 * 10-9 | |||

Manufacturer's product ID | ECN 1313 | EQN 1325 | ECN 1325 FS | EQN 1337 FS | ECN 1325 FS | EQN 1337 FS |

| 1) | See appendix B "Safety level overview for ACOPOS product family safety functions" in the SafeMOTION user's manual (MAACPMSAFEMC-ENG) in the Downloads section of the B&R website (www.br-automation.com.). There are additional limitations when combining B&R motors with a gearbox, see section "1.2.1 ACOPOSmulti SafeMOTION EnDat 2.2 and ACOPOS P3 SafeMOTION" in the SafeMOTION user's manual (MAACPMSAFEMC-ENG) in the Downloads section of the B&R website (www.br-automation.com). |

Availability | Available encoders / Order code (ee) | |||||

|---|---|---|---|---|---|---|

E0 | E1 | D0 | D1 | S0 | S1 | |

8LSN4...-0 | Yes | Yes | Yes | Yes | Yes | Yes |

8LSN5...-0 | Yes | Yes | Yes | Yes | Yes | Yes |

8LSN....-3 | --- | --- | --- | --- | --- | --- |

Nominal speed (nnn)

Nominal speed (nnn)

8LS | b | c | d | . | ee | nnn | ff | gg | - | h | |||||||||||

| 8LSN three-phase synchronous motors are available with different nominal speeds. The nominal speed is specified as part of the order number in the form of a 3-digit code (nnn). |

Order code (nnn) | |||||||

|---|---|---|---|---|---|---|---|

011 | 015 | 020 | 022 | 030 | 045 | 060 | |

Nominal speed nN [rpm] | 1100 | 1500 | 2000 | 2200 | 3000 | 4500 | 6000 |

Availability

8LSN4

Available nominal speeds nN [rpm] | |||||||

|---|---|---|---|---|---|---|---|

1100 | 1500 | 2000 | 2200 | 3000 | 4500 | 6000 | |

8LSN43 | --- | --- | --- | --- | Yes | --- | Yes |

8LSN44 | Yes | Yes | --- | --- | Yes | --- | Yes |

8LSN45 | --- | --- | --- | --- | Yes | --- | Yes |

8LSN46 | --- | --- | --- | --- | Yes | --- | Yes |

8LSN5

Available nominal speeds nN [rpm] | |||||||

|---|---|---|---|---|---|---|---|

1100 | 1500 | 2000 | 2200 | 3000 | 4500 | 6000 | |

8LSN54 | --- | --- | Yes | --- | Yes | Yes | --- |

8LSN55 | --- | --- | Yes | --- | Yes | Yes | --- |

8LSN56 | --- | --- | Yes | --- | Yes | Yes | --- |

8LSN57 | --- | --- | Yes | Yes | Yes | Yes | --- |

8LSN58 | --- | --- | --- | --- | --- | --- | --- |

Motor options (ff)

Motor options (ff)

8LS | b | c | d | . | ee | nnn | ff | gg | - | h | |||||||||||

See the following table for the corresponding code (ff) in the order key.

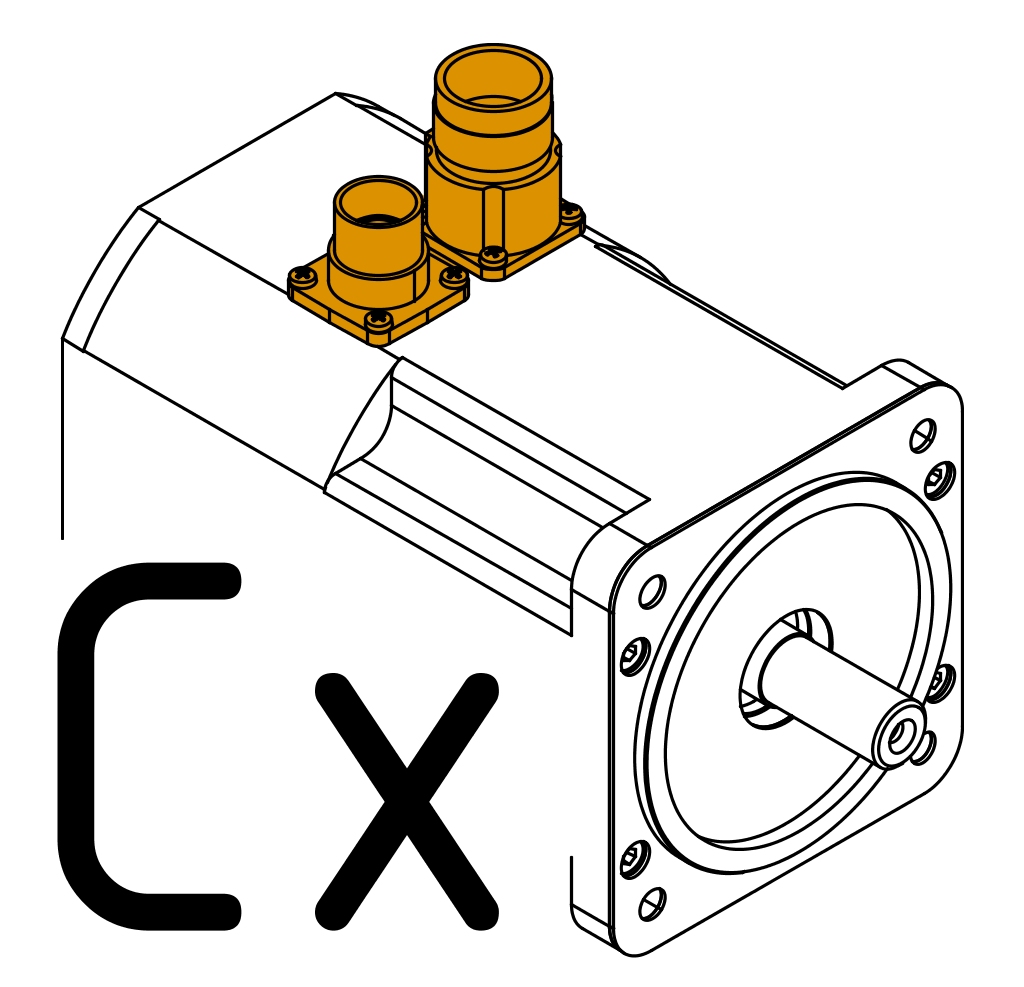

The first position in the code (ff) defines the connection direction with options Cx and Dx. The second position (e.g. x0, x1, x2, x3) defines all other motor options according to the table.

Motor option | Order code (ff) | ||||

|---|---|---|---|---|---|

Connection direction | Oil seal | Holding brake | Shaft end | ||

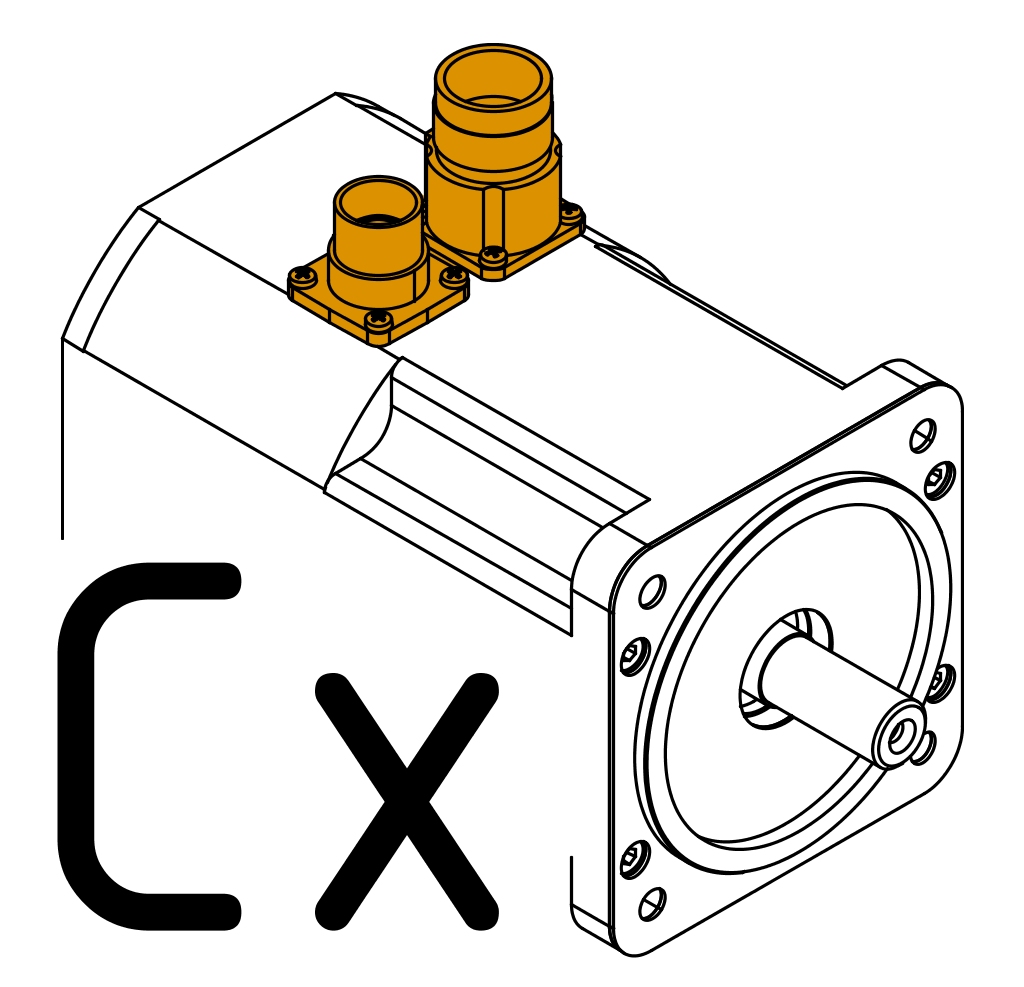

Straight (top connector)  Encoder and power cable: Separated with their own connections | --- | --- | Smooth shaft | C0 | |

--- | --- | Keyed shaft | C1 | ||

--- | Standard holding brake |  | Smooth shaft | C2 | |

--- | Keyed shaft | C3 | |||

Yes | --- | Smooth shaft | C6 | ||

Yes | --- | Keyed shaft | C7 | ||

Yes | Standard holding brake |  | Smooth shaft | C8 | |

Yes | Keyed shaft | C9 | |||

Available with motor encoder: DA, DB, EA, EB, E0, E1, R0, SA, SB, D0, D1, S0, S1 | |||||

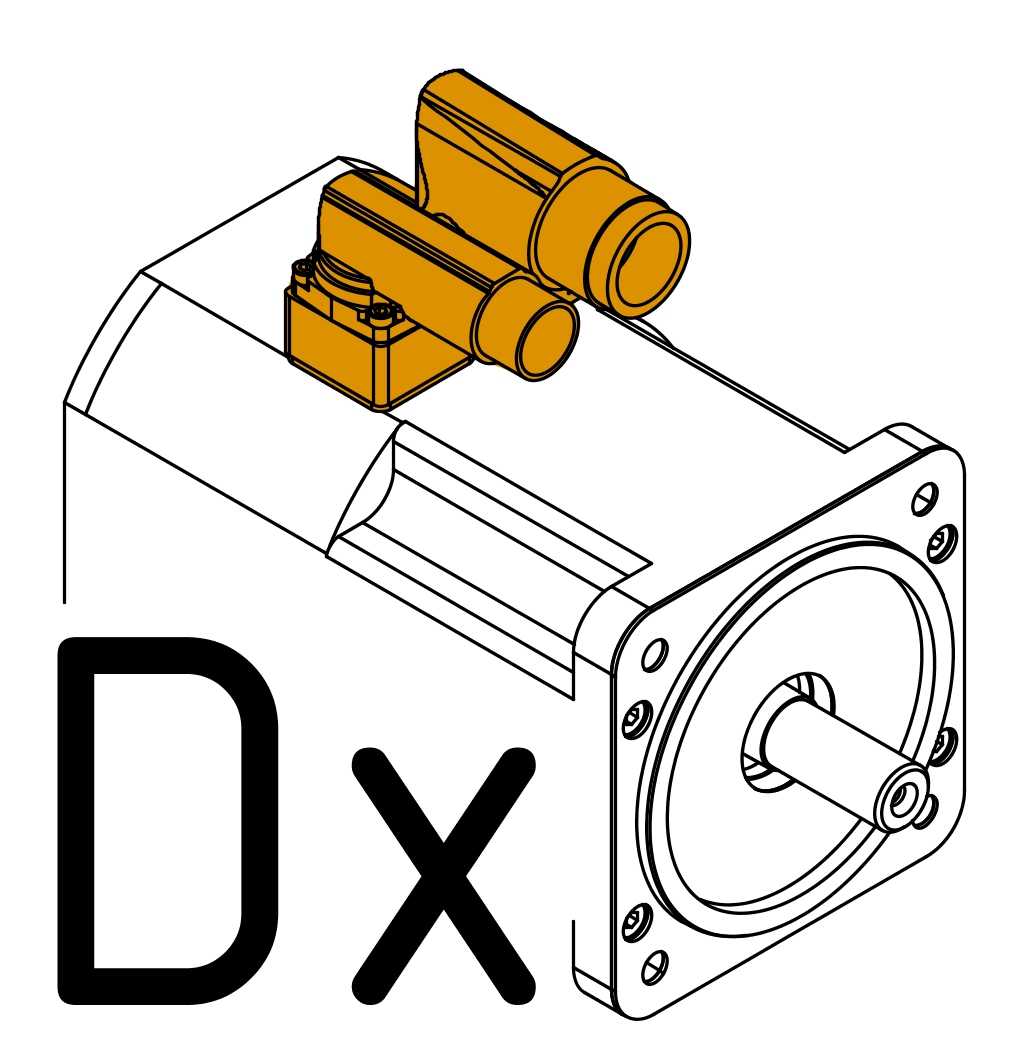

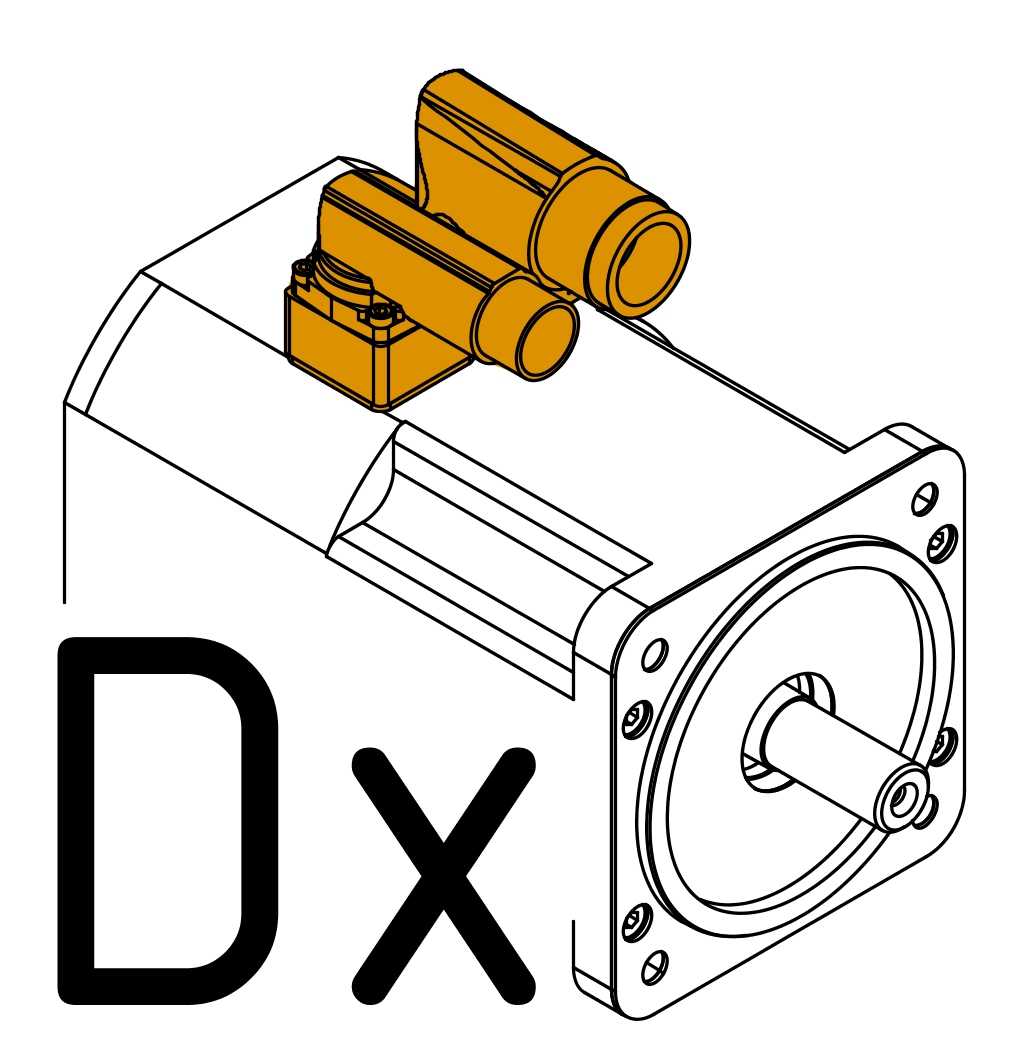

Angled (swivel)  Encoder and power cable: Separated with their own connections | --- | --- | Smooth shaft | D0 | |

--- | --- | Keyed shaft | D1 | ||

--- | Standard holding brake |  | Smooth shaft | D2 | |

--- | Keyed shaft | D3 | |||

Yes | --- | Smooth shaft | D6 | ||

Yes | --- | Keyed shaft | D7 | ||

Yes | Standard holding brake |  | Smooth shaft | D8 | |

Yes | Keyed shaft | D9 | |||

Available with motor encoder: DA, DB, EA, EB, E0, E1, R0, SA, SB, D0, D1, S0, S1 | |||||

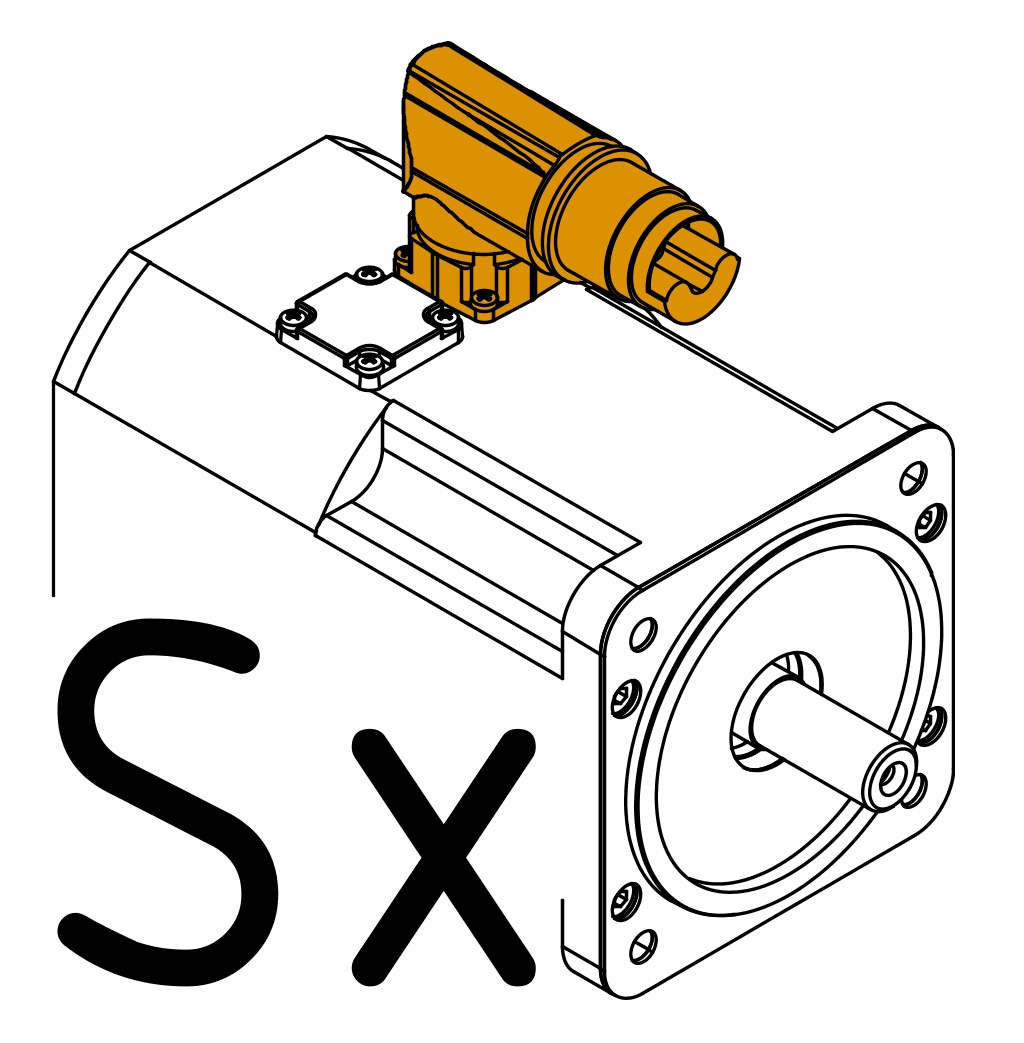

Single-cable solution (hybrid), angled, swivel connector  Encoder and power cable: Combined in one cable | --- | --- | Smooth shaft | S0 | |

--- | --- | Keyed shaft | S1 | ||

--- | Standard holding brake |  | Smooth shaft | S2 | |

--- | Keyed shaft | S3 | |||

Yes | --- | Smooth shaft | S6 | ||

Yes | --- | Keyed shaft | S7 | ||

Yes | Standard holding brake |  | Smooth shaft | S8 | |

Yes | Keyed shaft | S9 | |||

Available with motor encoder: DA, DB, SA, SB, D0, D1, S0, S1 | |||||

Connection direction (ff)

Connection direction (ff)

Power and encoder connections

8LSN three-phase synchronous motors are available with 3 connection options.

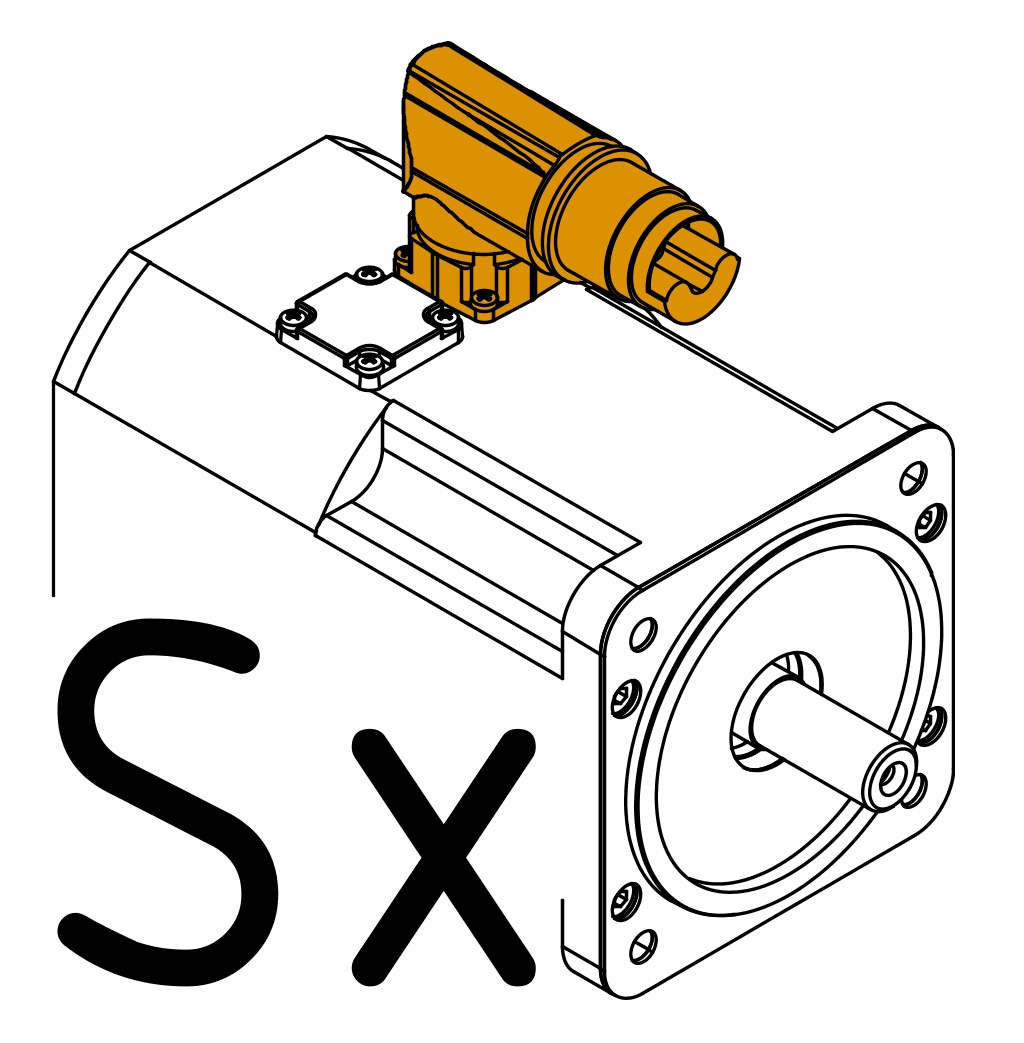

| Straight built-in connector Connection direction: Straight (top) Encoder and power cable: Separated with their own connections |

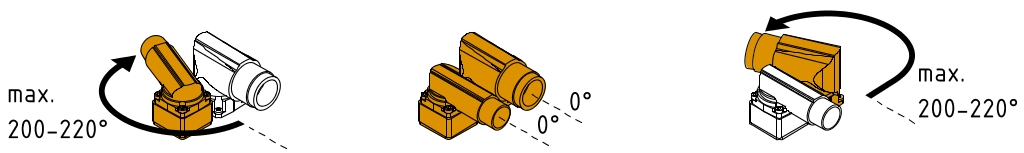

| Angled built-in connector Connection direction: Angled (swivel connector) Encoder and power cable: Separated with their own connections  Check the angle specifications (max. 200-220°) and the feasibility with regard to requirements using the CAD configurator (cad.br-automation.com). |

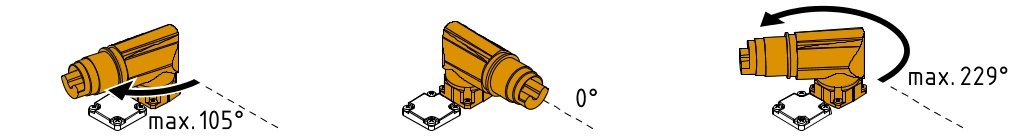

| Single-cable solution (hybrid) Connection direction: Angled, swivel connector Encoder and power cable: Combined in one cable  |

Oil seal (ff)

Oil seal (ff)

| All 8LS three-phase synchronous motors are available with a form A oil seal per DIN 3760.With an oil seal, the motors have IP65 protection per EN 60034-5. |

Servicing

To maintain functionality of the oil seal, it must be lubricated regularly with oil. An oil seal that is not lubricated will harden due to increased frictional heat and will eventually provide only dust protection.

Holding brake (ff)

Holding brake (ff)

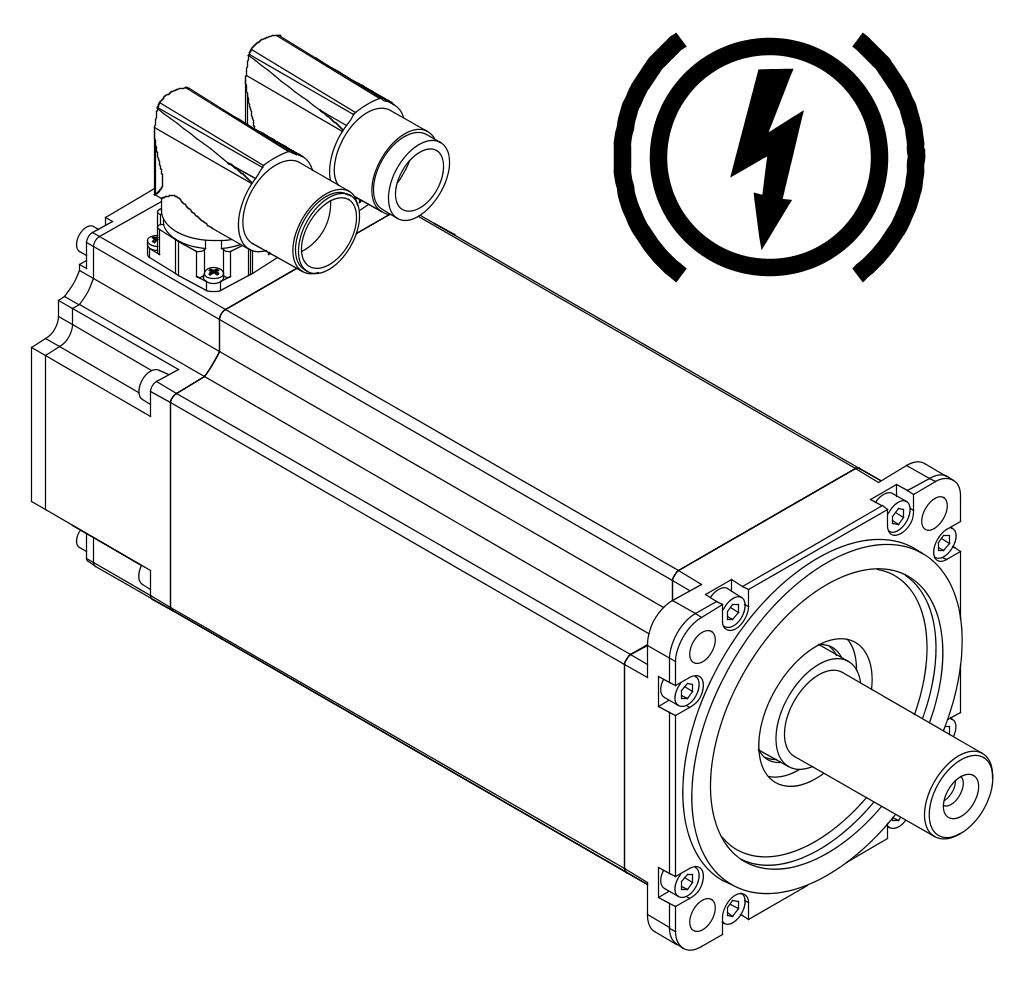

| 8LSN three-phase synchronous motors are available with a standard holding brake. It is installed directly behind the A-side flange on the motor and used to hold the motor shaft in a voltage-free state of the servo motor. |

Standard holding brake - Technical data

8LSN4 | 8LSN5 | |

|---|---|---|

Holding torque MBr [Nm] | 8 | 27 |

Connected load POn [W] | 18.0 | 24.6 |

Supply current IOn [A] | 0.75 | 1.03 |

Supply voltage UOn [VDC] | 24 (+6% / -10%) | |

Moment of inertia JBr [kgcm²] | 0.54 | 9.5 |

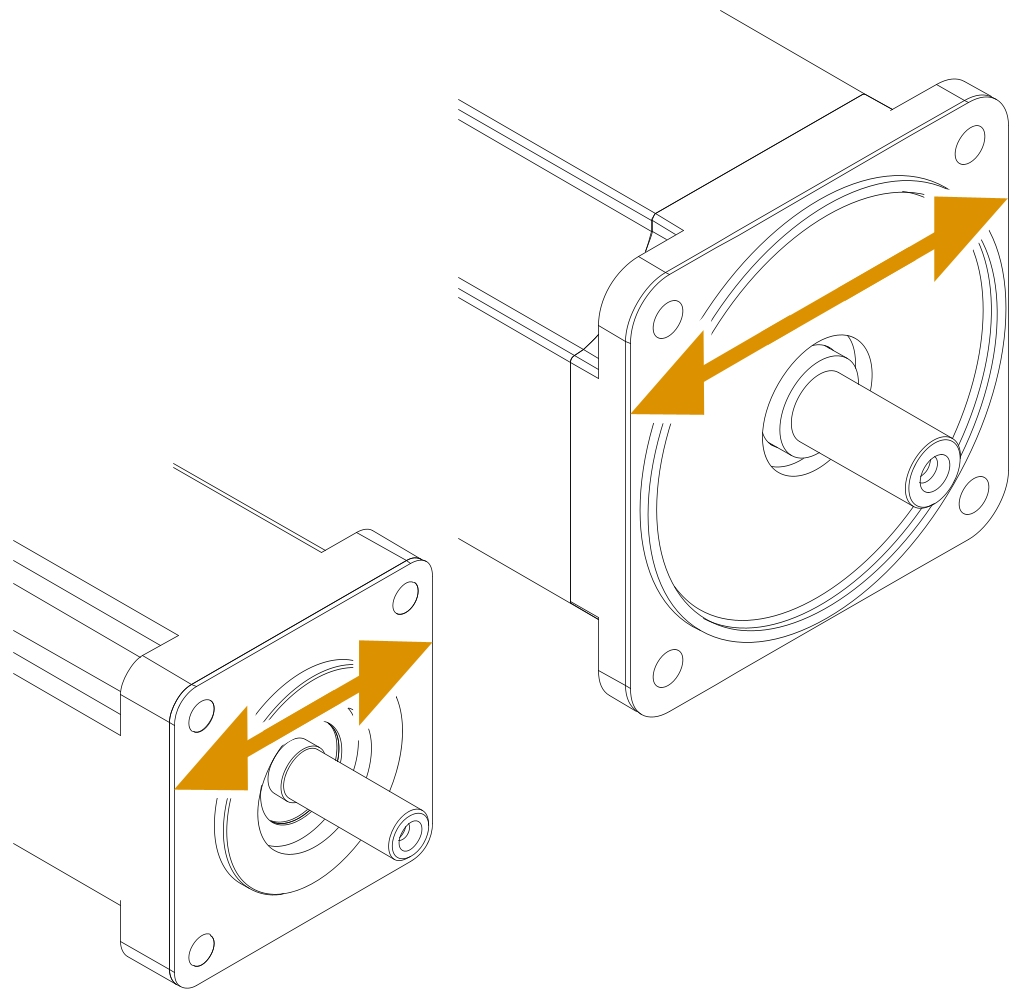

Shaft end (ff)

Shaft end (ff)

All 8LS three-phase synchronous motors have shaft ends per DIN 748. The shaft end is available in several variants, and availability can be determined in the corresponding table.

Variants

| Smooth shaft end A smooth shaft end is used for a force-fit shaft-hub connection and guarantees a backlash-free connection between the shaft and hub as well as a high degree of operating smoothness. The end of the shaft has a threaded center hole. |

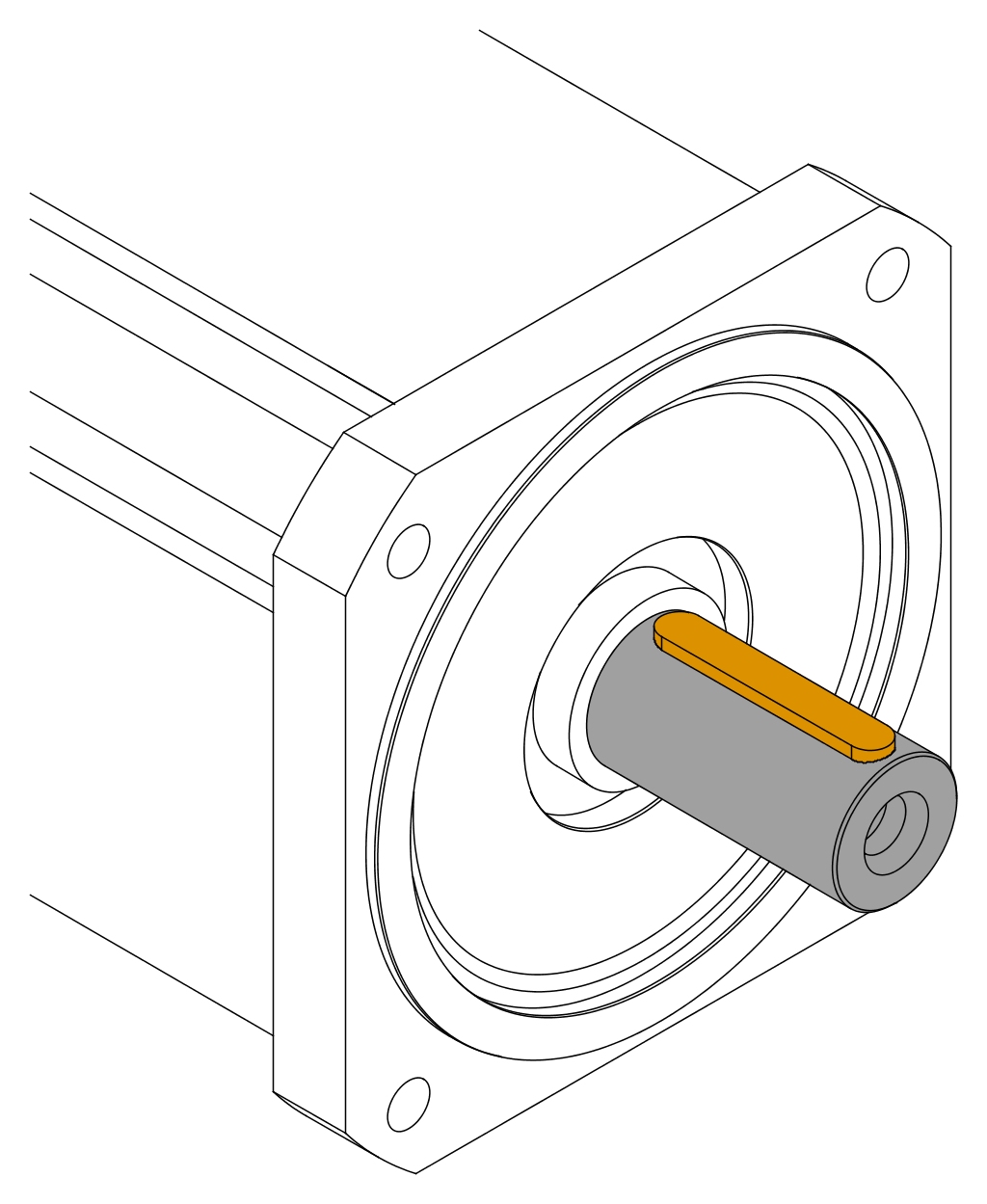

| Keyed shaft end A keyed shaft end is used for a form-fit torque transfer with low demands on the shaft-hub connection and for handling torque in a constant direction. The keyways for 8LS three-phase synchronous motors conform to keyway form N1 per DIN 6885-1. Form A keyed shafts that conform to DIN 6885-1 are used. Balancing motors with keyways is done using the shaft and fitment key convention per DIN ISO 8821. The end of the shaft has a threaded center hole that can be used to install machine actuators with shaft end cover plates. |

Special motor options (gg)

Special motor options (gg)

8LS | b | c | d | . | ee | nnn | ff | gg | - | h | |||||||||||

00...No special motor options

Motor version (h)

Motor version (h)

8LS | b | c | d | . | ee | nnn | ff | gg | - | h | |||||||||||

The motor version is specified as a code (h) in the order number.

0 ... Version 0 (motor encoders D0, D1, E0, E1, EA, EB, R0, S0 and S1)

3 ... Version 3 (motor encoders DA, DB, SA and SB)

Example order 1

Example order 1

A three-phase synchronous motor of type 8LSN45 with a nominal speed of 3000 rpm was selected for an application. Because of the construction, the cables can only be connected on the top side of the motor ("top" connection direction). The motor should also be equipped with a holding brake, a keyed shaft and a 16-line EnDat single-turn encoder.

The code (ee) for the encoder system is EA.

The (nnn) code for a nominal speed of 3000 rpm is 030.

The code (ff) for the other options (oil seal, holding brake, keyed shaft and connection direction) is C3.

The order number for the necessary motor is therefore 8LSN45.EA030C300-0.

Example order 2

Example order 2

A three-phase synchronous motor of type 8LSN56 with a nominal speed of 4500 rpm was selected for an application. Because of the construction, the cables can only be connected on the back of the motor (swivel connections). The motor should also be equipped with a holding brake, smooth shaft, oil seal and 16-line EnDat multi-turn encoder.

The code (ee) for the encoder system is EB.

The code (nnn) for a nominal speed of 4500 rpm is 045.

The code (ff) for the other options (oil seal, holding brake, smooth shaft end and connection direction) is D8.

The order number for the necessary motor is therefore 8LSN56.EB045D800-0.