The unique combination of features gives you a clear competitive edge:

IP69K protection

High-speed diverter is pivotal

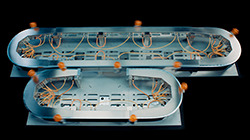

The absolutely unique high-speed ACOPOStrak diverters pass shuttles from one track circuit to another at full production speed. This opens up entirely new possibilities making manufacturing systems more agile and responsive.

ACOPOStrak diverters make it easy to divide and merge product flows. Fully electronic actuation means they are 100% free of wear and maintenance.

- Highlights

- Fully electronic diverter technology

- 100% wear free

- Divide and merge product flows at full speed

Maximum productivity

Compose custom sets in real time

Compose custom sets in real time

ACOPOStrak diverters let you group products into custom sets – in real time and with no changeover. Create custom six-packs of different beverages, for example.

Maximum production speed

Maximum production speed

The diverters pass shuttles from track to track reliably at full speed without any compromise in productivity.

Sorting on the fly

Sorting on the fly

ACOPOStrak diverters allow you to sort out individual defective products as soon as they are identified, saving the additional waste of further processing – including primary and secondary packaging materials. This opens up new dimensions of resource efficiency and boosts the quality factor of your OEE.

Enhanced handling and energy savings

Enhanced handling and energy savings

To achieve maximum dynamics and high throughput, ACOPOStrak generates a high thrust force that is used for process steps such as clamping. This makes ACOPOStrak more robust, reduces product wear and lowers energy consumption.

Hot-swappable shuttles

ACOPOStrak shuttles are hot-swappable and can be replaced in seconds – without any tools – for unprecedented availability. To switch products, the operator simply places the wheels of a new shuttle on the guides, and it is held in place by the force of permanent magnets alone. Include a pit lane in the track layout, and changeover and service can be performed with zero downtime.

Parallel processing

The product flow can be divided, pass through multiple processing stations and then merge further down the line. Time-critical processes are accelerated, cycle times are reduced and productivity increases.

Absolute design freedom

Your ACOPOStrak design

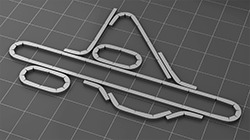

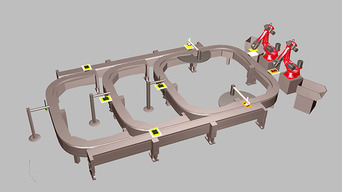

The versatile ACOPOStrak transport system grants you complete design freedom: Arrange track segments to perfectly match the needs of your site and your processes. All types of open and closed track circuits can be laid out on a grid as needed. The orientation of the track is completely up to you and the needs of your process.

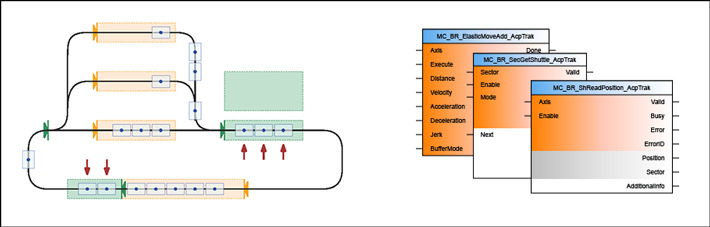

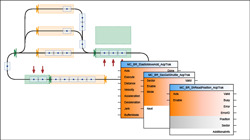

The core of the track system is a linear motor assembled from four types of modular segments: a straight segment, a 45° segment and two 22.5° segments – one curved to the right, the other to the left. With its modular, flexible system concept, ACOPOStrak enables completely new machine designs. Easily design your machine around the requirements of your process.

Guide rails

Shuttle | Straight guide | 45° | 90° | 135° | 180° |

|---|---|---|---|---|---|

|  |  |  |  |  |

Track length | 660 mm | 900 mm | 1140 mm | 1380 mm | 1620 mm |

Segments

Straight segment | Curved segment (right) | Curved segment (left) | Circular arc segment |

|---|---|---|---|

|  |  |  |

Radius | 305.58 mm | ||

Angle | 22.5° | 45° | |

Smart system software

Developers also benefit from process-oriented programming. They simply describe the rules that define the product flow on the track, rather than having to program a multitude of axes and shuttles individually. Autonomous traffic control with integrated collision avoidance takes further work off the hands of developers.

- Highlights

- Intuitive process flow programming

- Integrated collision avoidance

- 3D visualization/simulation

- Autonomous shuttle traffic control

Faster to market

We provide an extensive range of software functionality to get ACOPOStrak up and running with minimal time and effort. Sophisticated simulation functions let you test your application code early in development before deploying it on the real hardware. This shortens your development times considerably and helps you get your machine to market faster.