It's hard to imagine a modern automated production line without flexible workpiece handling. That's why OEMs like HB Systems are increasingly incorporating robots into their solutions to perform pick-and-place operations. With mapp Technology and openROBOTICS from B&R, doing so has never been easier. Robotics functions can simply be incorporated into PLC programs without any separate robot controllers or specialist training. This is demonstrated perfectly by the workpiece handling solution on a threading machine from HB Systems.

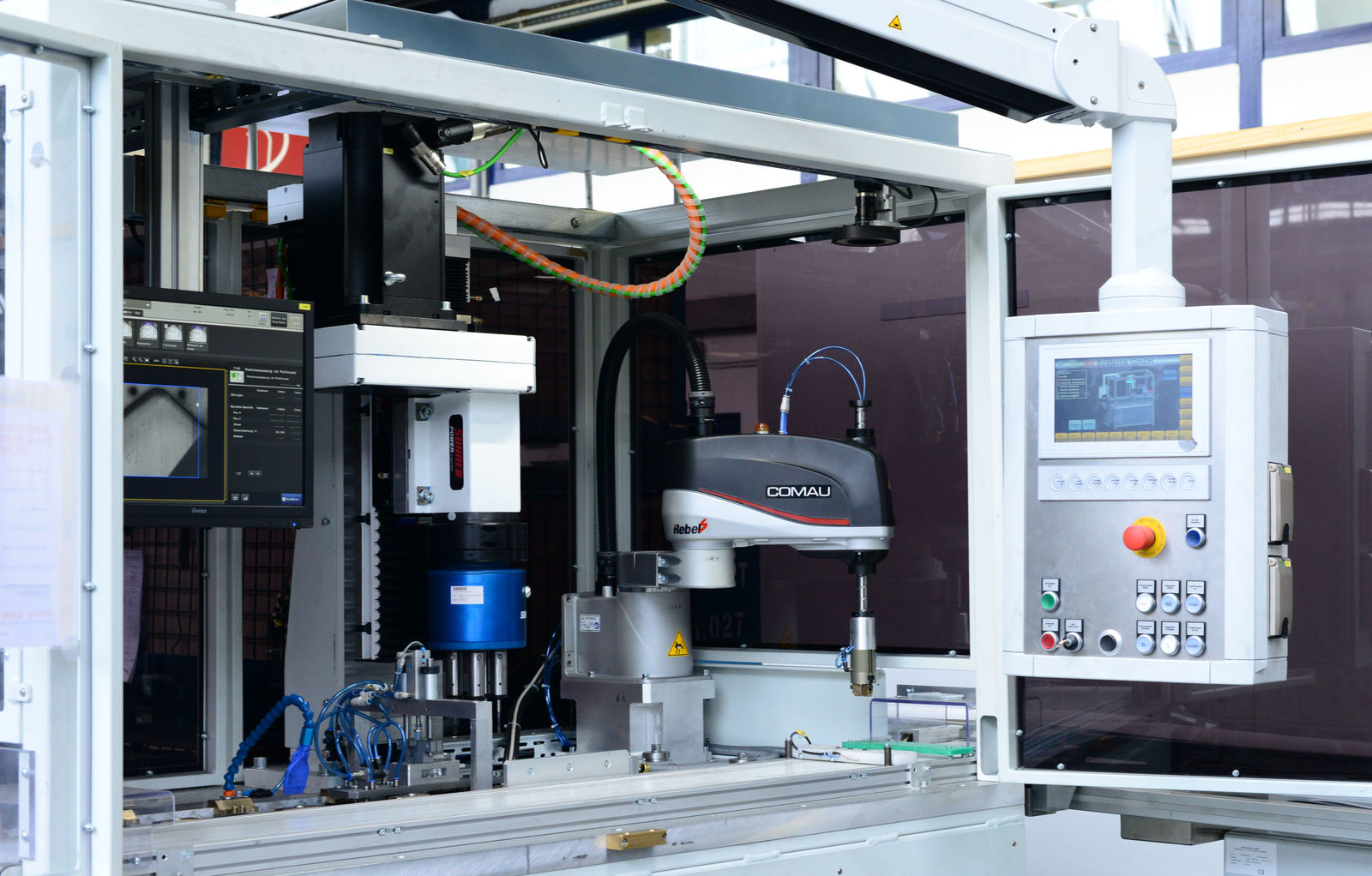

The pick-and-place task performed by the SCARA robot on the HB Systems threading machine is similar to those found in many machining and assembly lines. The position and angle of a newly received workpiece – in this case a pressed sintered metal component – are captured by camera and sent to a robot. The robot picks up the piece and maneuvers it into the correct position at the machining station.

At first glance, there's no outward indication of the innovative technology at work behind the scenes – technology that could revolutionize the way OEMs think about robotics: B&R's mapp Technology and openROBOTICS.

"In the past, we too have taken a very conventional approach to pick-and-place: we selected a robotics supplier and used their tailor-made control hardware," says Hans Bögelein, founder and CEO of HB Systems. "We outsourced the robotics programming so that we could concentrate fully on our core competency: designing automation solutions and inspection systems."

It's a reasonable decision, and one that many other OEMs have made in the past. Ultimately, implementing a robotics application requires extensive expertise and personnel with special training to use the robot manufacturer's development tool. This has often been a significant drain on small and medium-sized OEMs’ financial and human resources. As a result, senior staff have effectively been forced to choose an outsourcing model.

A combined hardware and software platform

Now, B&R and the robotics experts at COMAU have dealt OEMs an entirely new hand by creating openROBOTICS, which – for the first time – unifies robot and machine controllers on a combined hardware and software platform.

"The biggest advantage from our perspective as a PLC-oriented company, is that we can develop the robot application within our familiar engineering environment, Automation Studio, along with everything else. That means we can make any required changes to the robot functionality much faster and more flexibly than before," says the CEO, explaining the decision to use openROBOTICS.

B&R has developed a corresponding mapp component that relieves the user of tasks such as configuring the robot geometry, identifying the right transformation, coupling axes or tuning the servo drive. Handling tasks can be implemented without writing a single line of code.

Robot integration in just a few days

"We implemented the robotics functionality for our threading machine on our own in just a few days," says Bögelein. From placing the order for the automation components to commissioning the new machine, the whole process took just six weeks. Since then, it's been running as an inline system for an automotive supplier.

One reason for the rapid completion of the project was the decision to use mapp Technology to create a robotics application that integrates seamlessly into the rest of the application software. This allowed the OEM to continue using leveraging the collection of Structured Text modules it had been building over the years. This avoids long latency times for communication via fieldbus or cable between sequential and robot controllers. This in turn makes it easier to synchronize sequential and robot controllers, enabling greater positioning precision.

Minimal engineering and hardware costs

Thanks to openROBOTICS, the COMAU robot's control electronics are an integral feature of the B&R system landscape: just like every other axis in the system, the motors of the SCARA robot arm are controlled by ACOPOS servo drives using a common DC bus. As a result, braking energy can be recovered and fed to other motors throughout the system to both save energy costs and improve the CO2 footprint.

The openROBOTICS approach also has positive effects on hardware costs. Sequential control, robotics control and the HMI application all run on a single hardware platform, eliminating the need for a separate robot controller and display.

Integrated automation

For HB Systems' threading machine, an Automation PC 2100 is able to handle all the applications, with the HMI application displayed on a Power Panel T30 terminal. The image processing system – which is supplied by KEYENCE, as is the camera – is integrated via Ethernet/IP using an X20 interface module from B&R. HB Systems' fully integrated automation solution uses modules from the X20 lineup for communication throughout the production line, including modules providing integrated safety functions.

In addition to simplifying the process of engineering the control, HMI and safety applications, having all the main automation components so tightly integrated pays off in terms of diagnostics as well. Since they have direct access to axis errors and other alarms without having to go through external systems, for example, machine operators are able to identify the location and cause of a problem faster.

"Thanks to openROBOTICS and mapp Technology, we have been able to integrate robot functionality into our system software for the first time – in-house and with a manageable workload – and can further develop it and perform diagnostics without ever having to leave our familiar engineering environment," says Bögelein. "This makes us even less reliant on third parties and gives us added flexibility in how we design and maintain our systems."

| Dipl.-Ing. Hans Bögelein Founder and CEO, HB Systems "Thanks to openROBOTICS and mapp Technology, we have been able to integrate robot functionality into our system software for the first time – in-house and with a manageable workload – and can further develop it and perform diagnostics without ever having to leave our familiar engineering environment. This makes us even less reliant on third parties and gives us added flexibility in how we design and maintain our systems." |