Shaping the future of an industry

Additive manufacturing is rapidly evolving from a niche technology to an integral part of the modern manufacturing landscape. While the focus has been on prototyping, the industry is now poised for the next big growth step: industrialized, 24/7 production.

This change brings with it new challenges in the areas of standardization, certification, quality and lifecycle management. At B&R, we are ready to meet these challenges. Together with our customers and partners, we are driving the change and making additive manufacturing ready for production – faster, more flexible and more efficient. Let's shape the future of the industry together.

Integration into mass production

Additive manufacturing is increasingly being integrated into mass production through the development of hybrid systems that combine traditional and additive processes. This development enables more efficient production and opens up new possibilities for manufacturing complex geometries in high volumes.

Automation & process optimization

Automation plays a critical role in additive manufacturing, especially in post-processing and quality assurance. Advances in robotics and machine learning are enabling more efficient and consistent manufacturing processes.

Material diversity and development

There is a strong trend towards the development of new materials specifically optimized for additive manufacturing. This includes plastics and metals as well as advanced materials such as ceramics, biomaterials and composites that are tailored to specific industrial applications.

Sustainability and resource efficiency

Additive manufacturing is increasingly seen as a sustainable production method because it reduces material consumption and offers the opportunity to manufacture products locally, minimizing transportation costs and emissions. Work is also underway to make processes more energy efficient and to recycle materials.

Development and production cycles

By producing prototypes and functional parts directly, additive manufacturing significantly reduces the time from concept to market. This gives companies a significant competitive advantage in fast-moving markets.

Driving additive manufacturing with B&R

Investment security

Our end-to-end automation system offers a high level of investment protection thanks to a very high degree of compatibility between system generations. Our software projects are designed to work seamlessly with future hardware generations. We guarantee the long-term availability of our industrial PCs and panels. Our customers benefit from a complete solution.

High-precision drive systems

3D printers come in different sizes - from the smallest machines that produce components in the micrometer range with breathtaking precision to machines with huge build volumes in the cubic meter range. With its wide and scalable range of drive components, B&R offers the right solution for every printer size.

Safety technology

Some printing processes require high oxygen levels in the pressroom. Our integrated safety components provide a perfectly scalable solution for this requirement. Safe evaluation of the oxygen concentration sensor with the X20SAI or X20SAT is just as possible as a safe temperature input.

Machine design – compact & modular

A standard control cabinet for all machine variants, decentralized options and reduced cabling through daisy chaining enable efficient machine modularization. Other benefits include IP65 motor-integrated drives, IP67 remote I/O for installation outside the control cabinet and a reduced carbon footprint.

Lifecycle management

Additive manufacturing processes are increasingly evolving from prototyping to industrial series production. Machine availability is becoming more and more important - and automation systems from B&R play a decisive role in this. With the integrated Diagnostics Manager, service technicians can access all relevant information via web-based diagnostic pages. This results in simple and efficient maintenance and increased OEE availability.

Automated post-processing

Products manufactured with 3D printers often have to be reworked manually. As additive manufacturing processes continue to evolve, automated post-processing is becoming essential. With our industry-leading portfolio of ABB and Codian robotic equipment, we support machine manufacturers in the development of automated post-processing solutions, such as part handling, support removal and surface treatment.

Solution expertise and co-creation approach

In additive manufacturing, the ability to develop customized and innovative solutions plays a critical role. At B&R, we understand that each application and each challenge is unique. Our solution expertise is based on a deep understanding of our customers' specific requirements and our many years of experience in automation technology.

Success stories

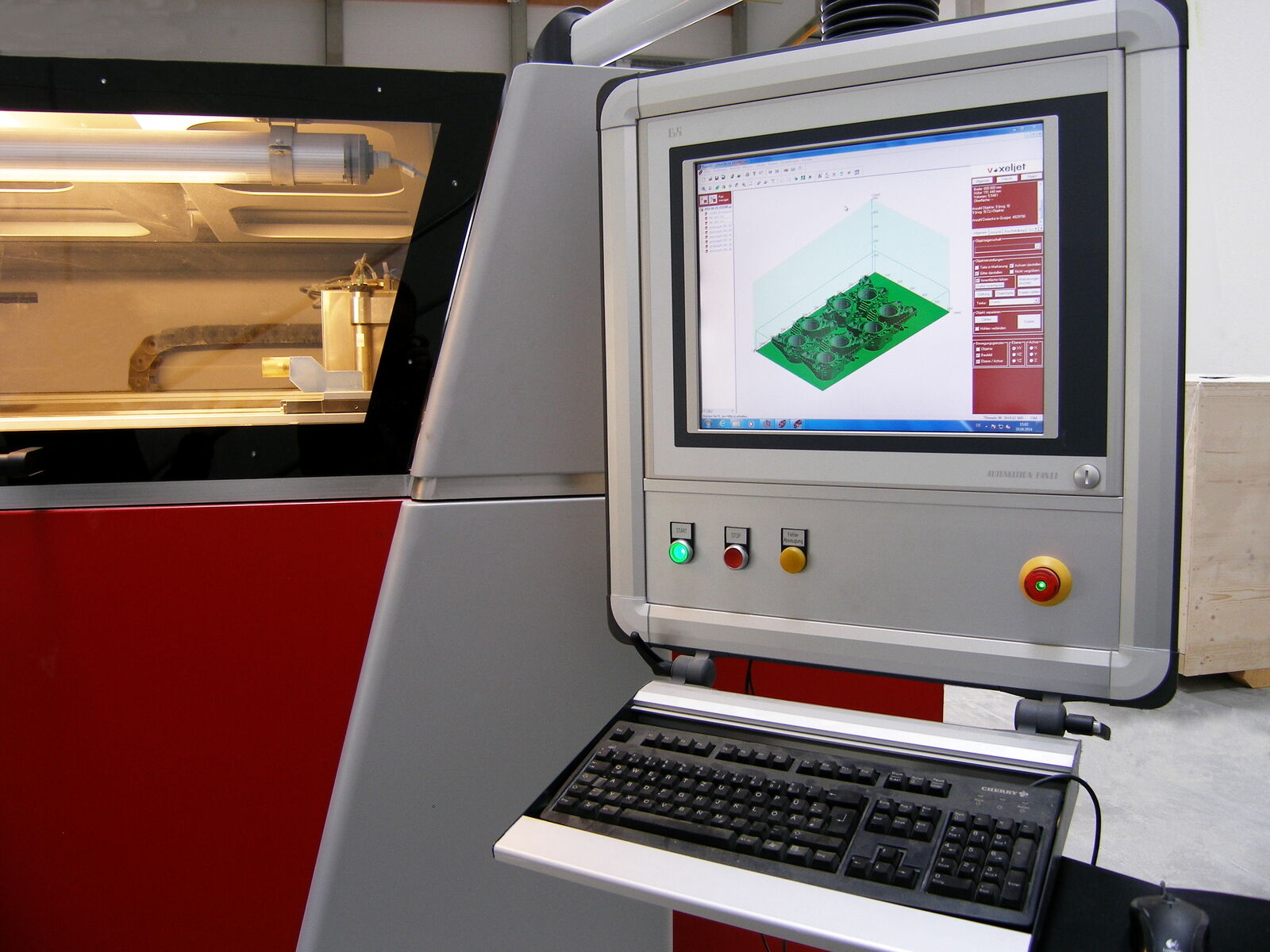

Print complex models easily

The challenge: Produce complex sand cores for metal castings, custom foil sets, functional plastic parts and high-precision architectural models in a matter of hours.

The solution: An adaptable, integrated automation and control solution based on powerful B&R technology ensures that even large print jobs are executed reliably, precisely and accurately. The HMI application runs on a PC, which also prepares the print data for the 3D printer.

Björn Matthes, Electrical Engineering Group Manager at voxeljet AG: "B&R's comprehensive product range, including integrated safety technology and a universal programming and configuration tool, convinced us. It offers everything we need and leaves us enough room for further innovative developments.

The partner for your solution - FAQs

Why is a solution provider like B&R important for additive manufacturing projects?

Why is a solution provider like B&R important for additive manufacturing projects?

Our services support our customers in every phase of the project - from needs analysis and design to implementation and commissioning of the entire automation solution. Our global network of local experts and application engineers is available to our customers anytime, anywhere.

What differentiates a solution provider from a component supplier?

What differentiates a solution provider from a component supplier?

- Professional support at every stage of the customer's project:

- Project management

- Creation of specifications

- Creation of software

- Implementation of concepts

- Commissioning

What are the other benefits?

What are the other benefits?

- Our standardized development and documentation processes provide maximum transparency and investment security. We guarantee qualified support worldwide and around the clock:

- Optional supply of subcontractors (e.g. panel builders)

- Factory assembled and tested control and I/O systems for maximum assembly efficiency

- Customer part number on packaging label

- Long-term availability with automatic end-of-life notification

Do you have any questions? - Talk to our industry expert.

Further contact options with B&R: Local partners and trade fair dates

Find a partner near you

Take advantage of our global network for end customers.

In addition to more than 200 B&R offices in over 70 countries around the world, we have a global network of value-added partners. B&R Value Providers work seamlessly with B&R to bring our products and services to your door. They combine in-depth knowledge of B&R technology with a deep understanding of your local market.