Innovative automation solutions for the future – Efficiency and precision for your industry

Experience how B&R takes your production processes to the next level with the latest technology, seamless integration and maximum flexibility in our Innovation Spotlight.

Open and secure, time-critical communications

OPC UA FX C2C (Controller-to-Controller) technology enables precise, secure, and time-critical data exchange between machines, ensuring optimal performance in demanding environments. Engineered for high-performance tasks with low, guaranteed latency, it is ideally suited for applications such as robotics and motion control. With its open, standardized design, OPC UA FX C2C fosters interoperability across diverse systems, supporting various Quality-of-Service (QoS) levels on shared networks. Combined with robust end-to-end security, it empowers manufacturers to build scalable, interoperable networks – driving efficiency and advancing the smart factories of the future.

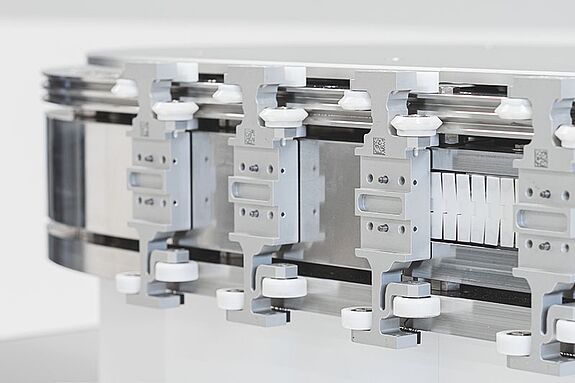

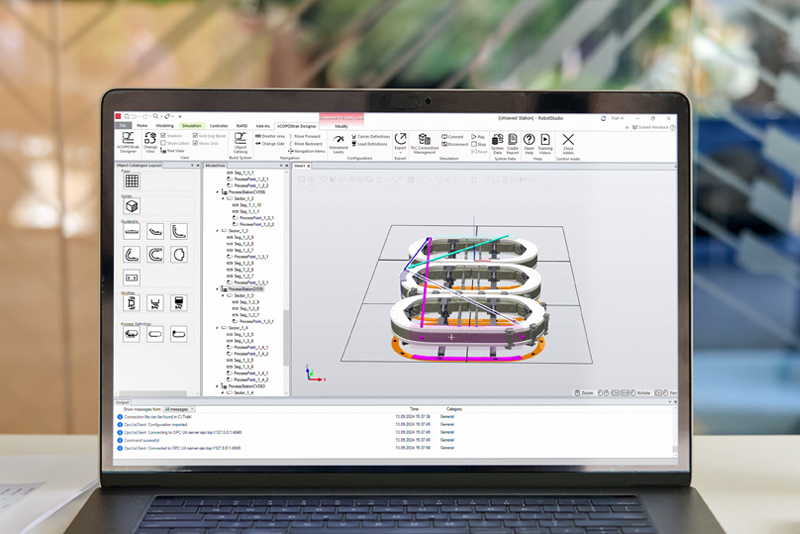

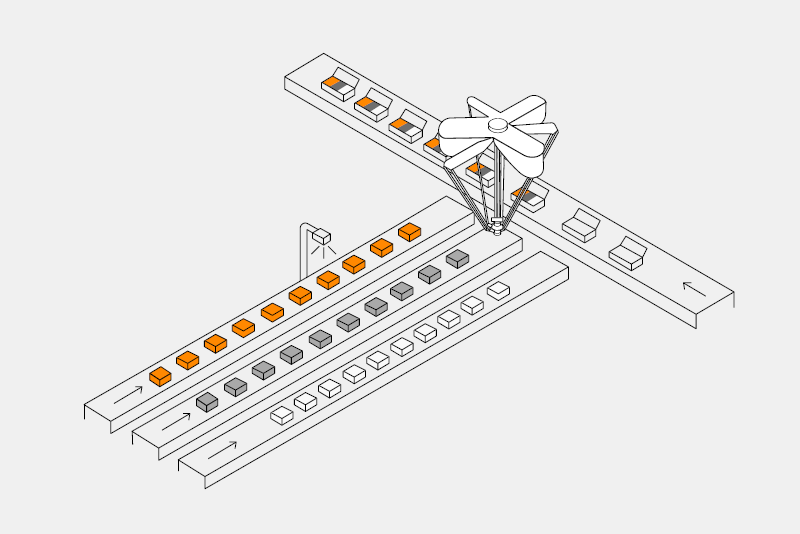

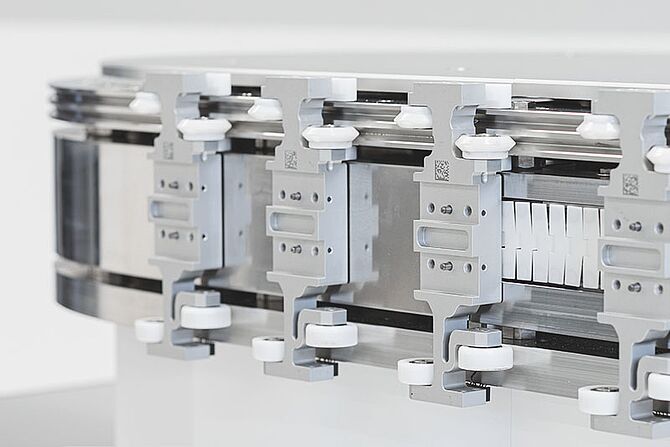

Track and conveyor hand-in-hand

ACOPOStrak Hybrid integrates intelligent and conventional transport with seamless transfer of products between tracks and conveyors. Ready-to-use software for automatic handover reduces development time. From intralogistics solutions with long transport distances to high-speed filling lines, ACOPOStrak Hybrid maximizes 3D space utilization and makes adaptive solutions economical in any situation.

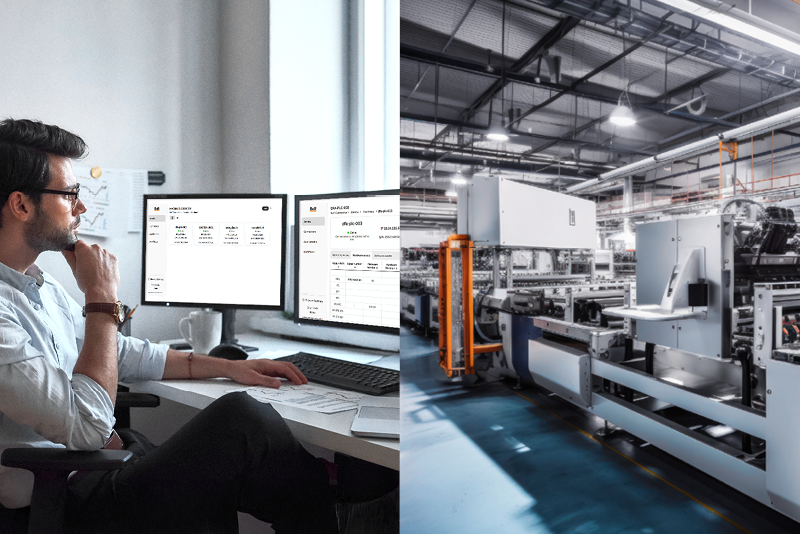

New automation engineering experience

Automation Studio Code offers engineering teams a whole new way to interact with their projects and each other. A modern, intuitive interface and advanced engineering features make work easier than ever. DevOps integration ensures smooth, efficient and reliable software delivery pipelines. With an AI-powered expert coding assistant and the flexibility of cloud-based collaboration, developers can do their best work and deliver smarter solutions faster. Discover more

Adaptive safety for the smart factory

With Safety+ B&R introduces an open approach to safety programming, compatible with tools like GitHub and Jenkins for agile development. An open data architecture and digital fingerprinting support flexible programming languages and data types, making safety applications as productive as standard automation. With traceable changes down to individual functions, Safety+ empowers engineers to innovate safety solutions quickly – without compromising control. Discover more

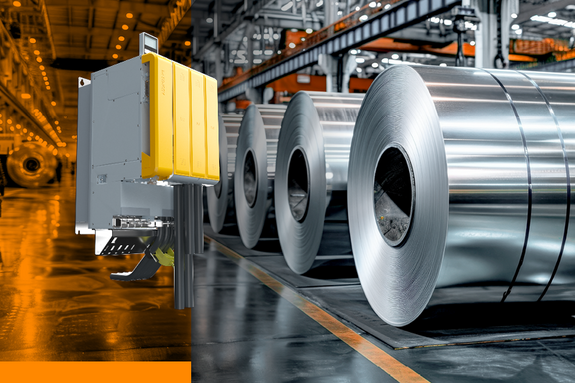

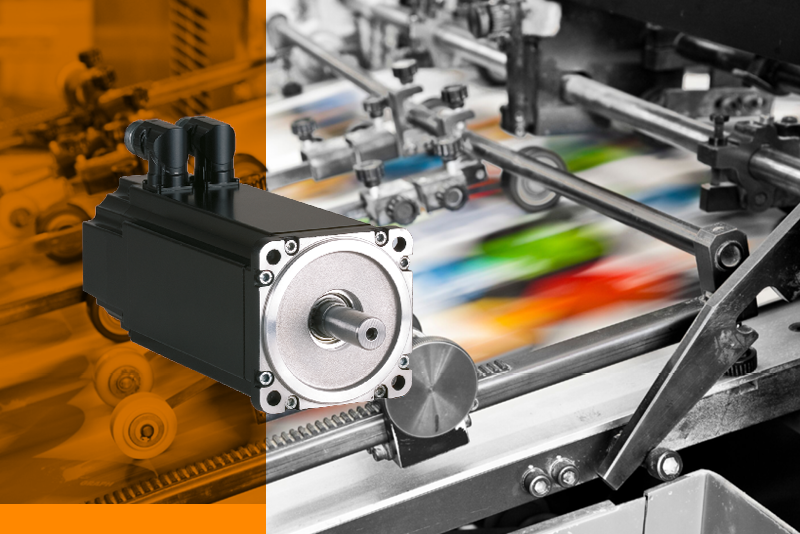

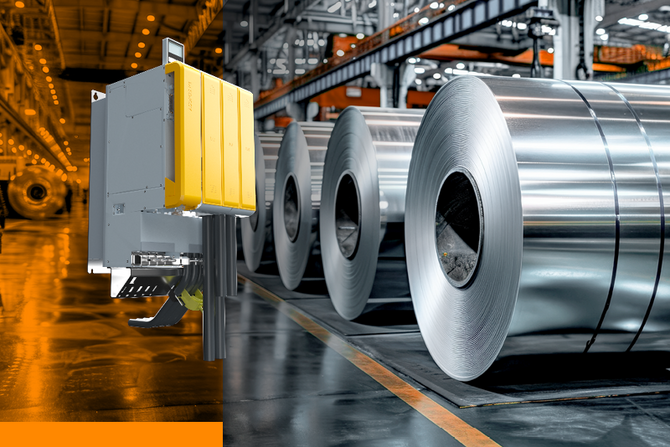

Powerful servo for harsh environments

A power extension to the ACOPOS P3 servo drive family delivers double the power density and up to 80 kW, ideal for high-demand industries like plastics, paper, metals, and textiles. With a 60% smaller cabinet footprint, these robust, dustproof drives simplify layouts and reduce maintenance. Accurate fan control, adaptive PWM switching frequency, and an intelligent notch filter for vibration suppression boost reliability and extend lifespan. The new ACOPOS P3 provides high performance for both single and double axes with 50 µs cycle times.

Cloud-based collaborative engineering

Explore a cloud-based collaborative environment designed to streamline automation projects directly from your browser. It breaks down development silos, enabling seamless cloud collaboration across distributed teams and provides a unified project overview. Key features include easy integration with your repositories as GitHub, a clear view of the codebase, and the ability to launch development environments with a single click – dependencies and versions are pre-set for immediate coding. Share projects securely with colleagues, partners, or clients, enhancing collaboration while maintaining strict access control.

Robotics goes multicore

With Automation Studio 6 and mapp Technology 6, machine builders can now run up to three times more robots on a single Automation PC. This multicore capability allows more efficient use of computational power, freeing up capacity for complex applications or non-real-time tasks – all without the need for advanced multi-threading programming. The result is higher performance, reduced programming complexity, and a smaller cabinet footprint, making robotics control more powerful and cost-effective.

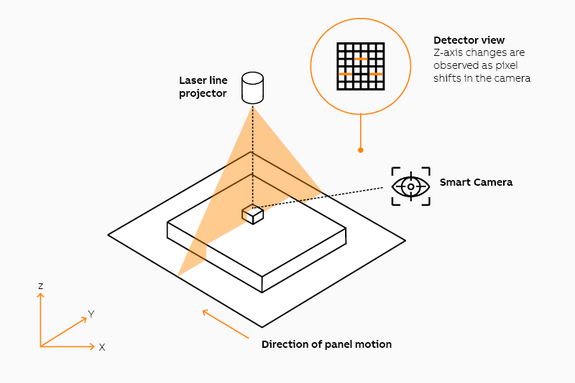

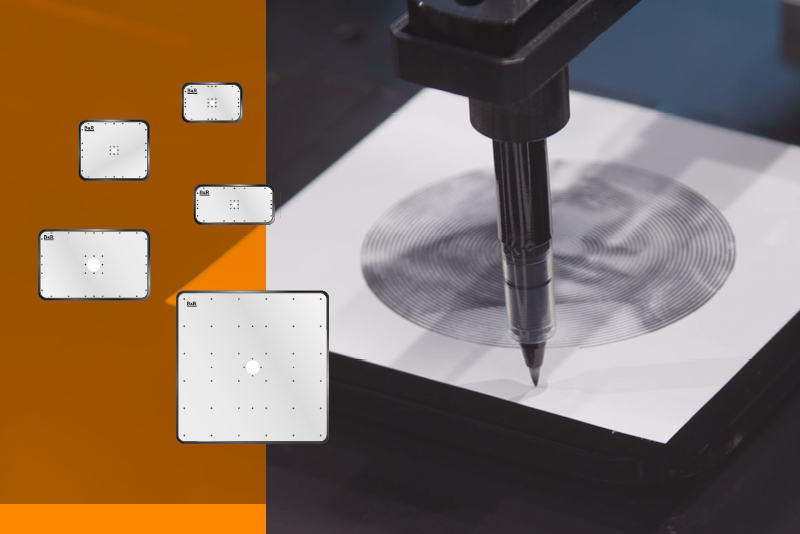

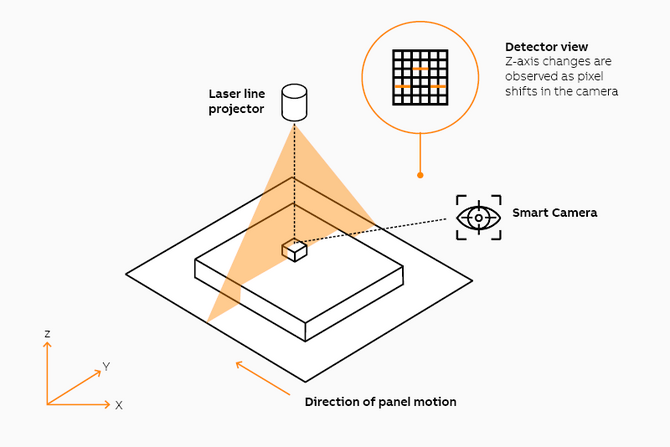

3D vision tasks: Cost-optimized

A clever extension for B&R smart sensors and cameras uses laser triangulation with FPGA preprocessing to deliver a cost-optimized solution for solving 3D tasks in mid-range applications. B&R's 2.5D vision solution captures moving objects to enable height monitoring, sorting, volume estimation and more. Machine builders can simplify system complexity with an integrated system – e.g. no need for a transducer. Vision can be synchronized to highly dynamic movements with nanosecond precision. End users benefit from easy operation, higher OEE, and reduced energy consumption and hardware footprint – all with the precision of advanced 2D algorithms.

Welcome to our innovation showcase

Where our latest breakthroughs and big ideas take center stage. Where we discover what happens when a passion for pushing limits meets a hunger for sustainable productivity in a world of constant change.

Starting November 12, 2024, we will be bringing you regular updates with new groundbreaking innovations. We invite you to join us on this journey and be the first to hear about each new arrival in the arena of open, intelligent machine automation.